5S is an improvement process to eliminate waste that originates from a poorly organized workplace/area. It is the basic tool and foundation stone of Lean manufacturing, TPM, TQM, or any organizational process improvement activity. Without 5S practice, an organization cannot succeed in improving the product & process quality. This article lists 1S, 2S, and 3S audit points along with 1S 2S audit checklist sample.

Table of Contents

5S full form in Japanese and English language

- Seiri or Sorting out

- Seiton or Set in Order or Organize

- Seiso or Shine or Sweep

- Seiketsu or Standardize

- Shitsuke or Sustain or Self Discipline

1s 2s Audit Checklist

1s Audit Checklist

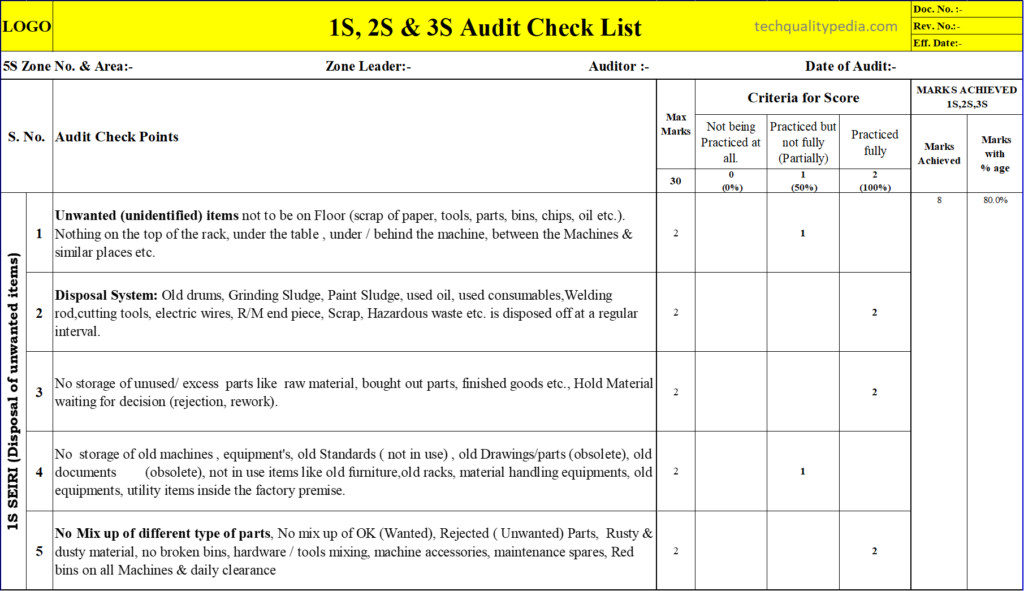

1S Meaning: Seiri – Sorting Out (Disposal of unwanted items)

It helps to segregate necessary & unnecessary items and eliminates unwanted items.

- Unwanted (unidentified) items not to be on the Floor (a scrap of paper, tools, parts, bins, chips, oil, etc.). Nothing on the top of the rack, under the table, under/behind the machine, between the Machines & similar places, etc.

- Disposal System: Old drums, Grinding Sludge, Paint Sludge, used oil, used consumables, Welding rods, cutting tools, electric wires, R/M end pieces, Scrap, Hazardous waste, etc. are disposed off at regular intervals.

- No storage of unused/ excess parts like raw material, bought-out parts, finished goods, etc., Hold material waiting for decision (rejection, rework).

- No storage of old machines, equipment, old standards (not in use), old drawings/parts/documents (obsolete), not-in-use items like old furniture, old racks, material handling equipment, old equipment, or utility items inside the factory premise.

- No mix-up of different types of parts, No mix-up of OK (wanted), Rejected (unwanted) Parts, Rusty & dusty material, no broken bins, hardware/tools mixing, machine accessories, maintenance spares, Red bins on all machines & daily clearance.

1s audit checklist with scoring criteria:

2s Audit Checklist

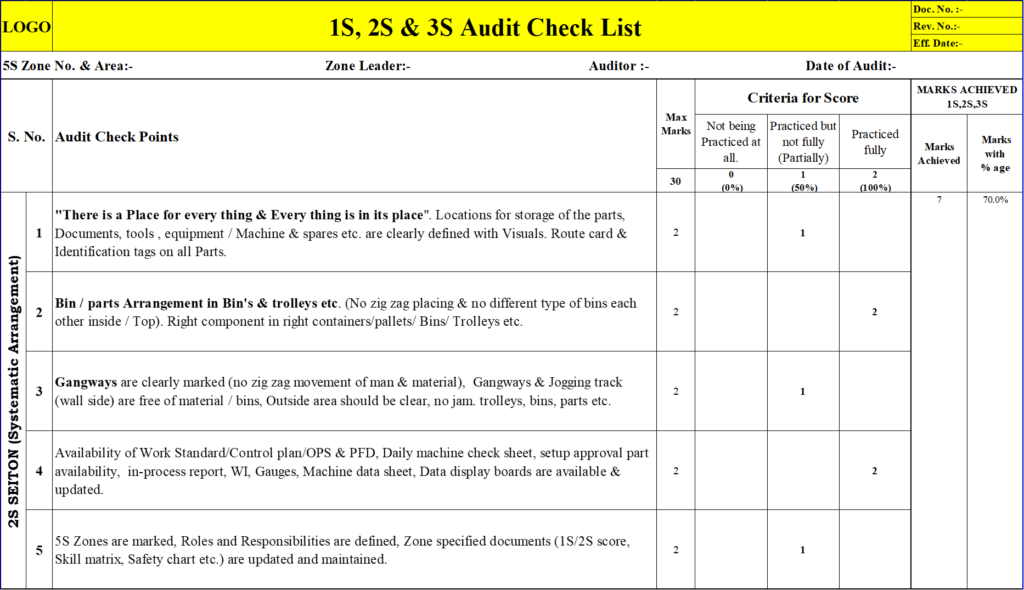

2S Meaning: Seiton – Set in Order – Organize – Systematic Arrangement

This step essentially means arranging items in a systematic way, for easy accessibility and using them in the best order.

- “There is a place for everything & everything is in its place”. Locations for the storage of the parts, Documents, tools, equipment / Machine & spares, etc. are clearly defined with Visuals. Route card & Identification tags on all Parts.

- Bin/parts Arrangement in bin & trolleys etc. (No zig-zag placing & no different type of bins each other inside / Top). The right component in the right containers/pallets/ Bins/ Trolleys etc.

- Gangways are clearly marked (no zig-zag movement of man & material), Gangways & Jogging track (wall side) are free of material/bins, Outside area should be clear, no jam. trolleys, bins, parts etc.

- Availability of Work Standard/Control plan & PFD, Daily machine check sheet, setup approval part availability, in-process report, WI, Gauges, Machine data sheet, and data display boards are available & updated.

- 5S zones are marked, roles and responsibilities are defined, and zone-specified documents (1S/2S score, Skill matrix, Safety chart, etc.) are updated and maintained.

2s audit checklist with scoring criteria:

3s Audit Checklist

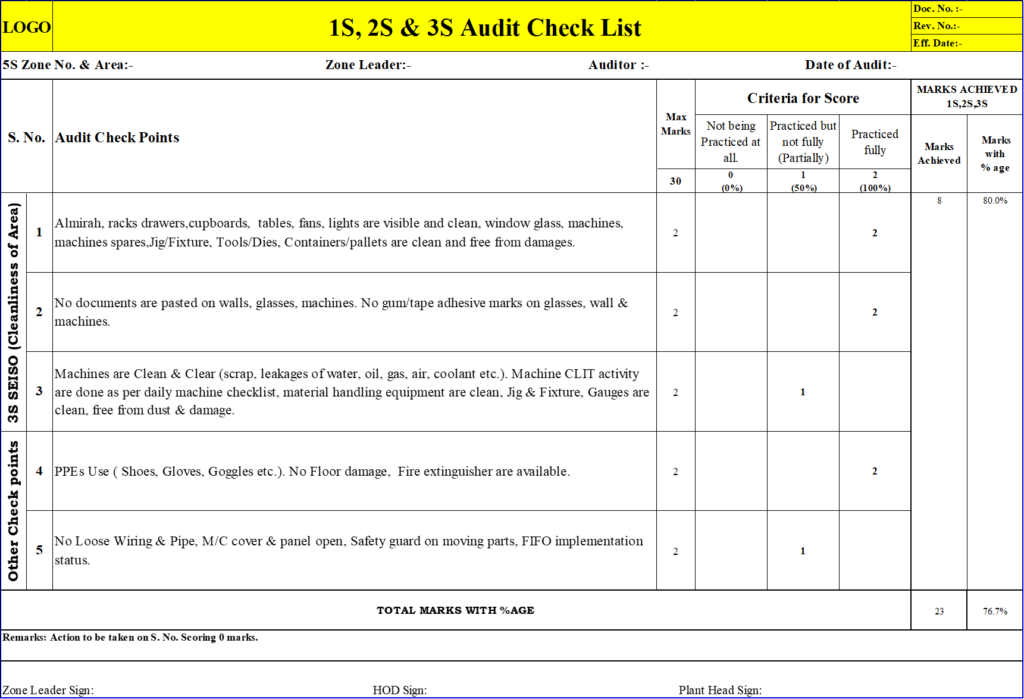

3S Meaning: Seiso – Shine – Sweep (Shine everything-cleaning.)

This step makes the workplace neat & clean by eliminating dirt, dust & other foreign matter.

- Almirah, racks drawers, cupboards, tables, fans, and lights are visible and clean, window glass, machines, machines spares, Jig/Fixture, Tools/Dies, and Containers/pallets are clean and free from damage.

- No documents are pasted on walls, glasses, or machines. No gum/tape adhesive marks on glasses, walls & machines.

- Machines are Clean & Clear (scrap, leakages of water, oil, gas, air, coolant, etc.). Machine CLIT activities are done as per the daily machine checklist, material handling equipment is clean, Jigs & Fixtures, and Gauges are clean, and free from dust & damage.

3s audit checklist with scoring criteria:

Other Safety Checkpoints

- PPEs Use ( Shoes, Gloves, Goggles etc.). No Floor damage or fire extinguishers are available.

- No Loose Wiring & Pipe.

- No M/C cover & panel open.

- Safety guard on moving parts.

I don’t even know howw I ended up here, but I thought tthis post was great.

I do not know who you are but definitely you

are goiung to a famous blogger iff you aren’t already 😉 Cheers! http://boyarka-Inform.com/