VDA stands for Verband der Automobilindustrie. VDA 6.x series is a German Quality Management System Standard used for the effective implementation and maintenance of a QMS in the Automotive industry and its supply chain. VDA 6.3 process audit standard is a part of the VDA6.x family which is used to evaluate the effectiveness of manufacturing processes within an organization, especially in the automotive sector. VDA 6.3 standard is crucial for ensuring that the manufacturing processes are effective, efficient, reliable, and capable of consistently generating high-quality products.

The VDA 6.3 process audit is integrated into a company’s QM system and contributes to the fulfillment of the requirements according to the IATF 16949:2016 QMS standard.

Table of Contents

VDA 6.x Series | Quality Management System Standards of the German Automotive Industry

VDA 6.x family included 8 volumes:

VDA 6.1: Quality Management System Audit – for Serial Production

VDA 6.2: Quality Management System Audit – for Service organizations

VDA 6.3: Process Audit – for evaluating, controlling, and improving the manufacturing process performance of the automotive industry.

VDA 6.4: Quality Management System Audit – for Production Equipment

VDA 6.5: Product Audit – for Guidelines to determine the quality assurance effectiveness and the capability of the production process by product verification/examination.

VDA 6.6: Process Audit – for other services

VDA 6.7: Process Audit – for Production Equipment

VDA 6.8: Process Audit – for Logistics

Note: Certification requirements only for VDA 6.1, VDA6.2 and VDA 6.4

VDA 6.3 Process Audit | Key Aspects

-

Objective:

- The primary goal of a VDA 6.3 process audit is to assess and improve the effectiveness of processes within an organization. This involves identifying areas for improvement to enhance product quality, reduce waste, and improve overall performance.

-

Scope:

- VDA 6.3 audits typically cover all aspects of the production process, from planning and development to production and delivery. This includes evaluating process management, product development, production processes, and customer service.

-

Audit Structure:

- The VDA 6.3 audit process is divided into several stages:

- Planning: Defining the scope, objectives, and criteria for the audit.

- Preparation: Gathering necessary information and documentation.

- Execution: Conducting the audit through interviews, observations, and document reviews.

- Reporting: Documenting findings, conclusions, and recommendations.

- Follow-up: Ensuring that corrective actions are implemented and effective.

- The VDA 6.3 audit process is divided into several stages:

-

Process Elements:

The standard emphasizes various process elements, including:

- Process Management: Assessing how well processes are managed, including planning, resource allocation, and risk management.

- Product Development: Evaluating the processes involved in designing and developing products, including design reviews and validation.

- Production and Delivery: Reviewing manufacturing processes, quality control measures, and logistics.

- Customer Interaction: Analyzing how customer requirements are captured and addressed.

-

Audit Criteria:

- Auditors use specific criteria to evaluate processes, which may include compliance with industry standards, effectiveness of process controls, and alignment with organizational goals.

-

Benefits:

- Implementing VDA 6.3 process audits helps organizations achieve:

- Improved process efficiency and effectiveness.

- Higher product quality and reliability.

- Better customer satisfaction and compliance with industry standards.

- Identification and mitigation of potential risks.

- Implementing VDA 6.3 process audits helps organizations achieve:

-

Training and Certification:

- Auditors need to be properly trained and certified to conduct VDA 6.3 audits. This ensures they have the necessary skills and knowledge to assess processes and provide valuable insights effectively.

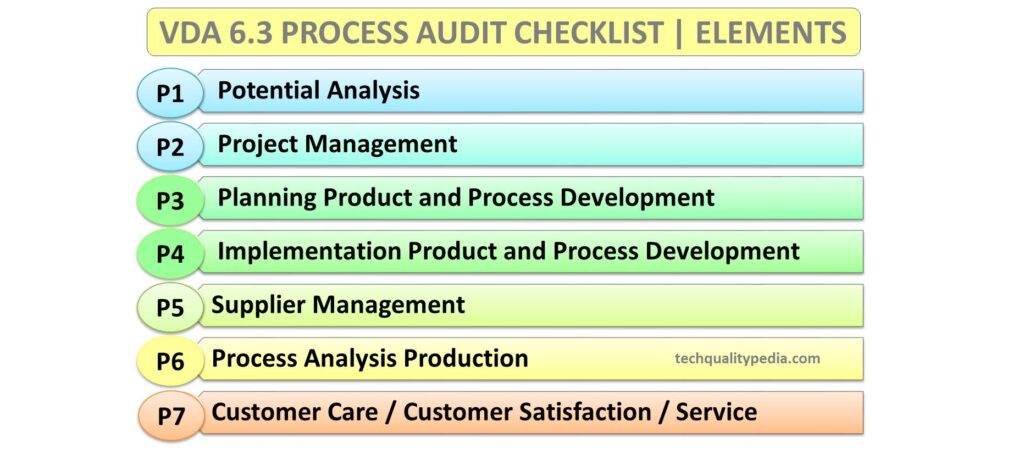

VDA 6.3 Process Audit Checklist | Elements

VDA 6.3 was published for the first time in 1998 and was revised in 2010, 2016, and 2023 (current edition).

Audit Report VDA 6.3 Potential Analysis (P1) excerpt from VDA 6.3 questionnaire/checklist.

| P2 | Project Management | |

| 2.1 | Is a project management established with a project organization? | |

| 2.2 | Are all resources required for the project implementation planned and available and are changes reported? | |

| 2.3 | Is there a project plan and has this been agreed with the customer? | |

| 2.4 | Is the advanced product quality planning implemented within the project and monitored for compliance? | |

| 2.5 | Are the procurement activities of the project implemented and monitored for compliance? | |

| 2.6 | Is change management within the project ensured by the project organization? | |

| 2.7 | Is there an escalation process established and is this effectively implemented? | |

| P3 | Planning Product and Process Development | |

| 3.1 | Are the specific product and process requirements available? | |

| 3.2 | Is the feasibility comprehensively evaluated according to the product and process requirements? | |

| 3.3 | Are the activities for the product and process development planned in detail? | |

| 3.4 | Are the activities planned for customer care/customer satisfaction/customer service and field failure analysis? | |

| 3.5 | Have the necessary resources been taken into account for the product and process development? | |

| P4 | Implementation Product and Process Development | |

| 4.1 | Are the actions from product and process development plans implemented? | |

| 4.2 | Are personnel resources available and are they qualified to ensure the start of the serial production? | |

| 4.3 | Are the material resources available and suitable to ensure the start of serial production? | |

| 4.4 | Are the required approvals and releases for the product and process development available? | |

| 4.5 | Are the manufacturing and inspection specifications derived from the product and process development and are they implemented? | |

| 4.6 | Is a performance test carried out under series conditions for the series release? | |

| 4.7 | Are the processes established for securing customer care/customer satisfaction/customer service as well as the field failure analysis? | |

| 4.8 | Is there a controlled method for the product handover from development to serial production? | |

| P5 | Supplier Management | |

| 5.1 | Are only approved and quality capable suppliers used? | |

| 5.2 | Are customer requirements taken into account in the supply chain? | |

| 5.4 | Are the necessary releases available for purchased products and services? | |

| 5.5 | Is the agreed-upon quality of purchased products and services ensured? | |

| 5.6 | Are incoming goods delivered and stored appropriately? | |

| 5.7 | Are personnel qualified for the various tasks and are responsibilities defined? | |

| P6 | Process Analysis Production | |

| P6.1 | What goes into the Process? (Process Input) | |

| 6.1.1 | Has the project been transferred from development to serial production and is a reliable start guaranteed? | |

| 6.1.2 | Are the necessary quantities/production batch sizes of incoming materials available at the agreed-upon time and at the correct storage location/workstation? | |

| 6.1.3 | Are incoming materials stored appropriately and are transport facilities/packing arrangements suitable for the special characteristics of the incoming materials? | |

| 6.1.4 | Are the necessary identifications/records/approvals available and allocated appropriately to the incoming materials? | |

| P6.2 | Are all Production Processes controlled? Process Management | |

| 6.2.1 | Are the requirements of the control plan complete and have they been effectively implemented? | |

| 6.2.2 | Does a repeat release for the restart of production take place? | |

| 6.2.3 | Are special characteristics managed in the production? | |

| 6.2.4 | Are non-released and/or defective parts managed? | |

| 6.2.5 | Is the flow of materials and parts secured against mixing / wrong items? | |

| P6.3 | What Functions support the Process? (Personnel Resources) | |

| 6.3.1 | Are the employees able to fulfill their given tasks? | |

| 6.3.2 | Do the employees know their responsibilities and authority in the monitoring of the quality of product and process quality? | |

| 6.3.3 | Are the necessary personnel resources available? | |

| P6.4 | What Means are used to implement the Process? (Material Resources) | |

| 6.4.1 | Can the product-specific requirements from the customer be met with the manufacturing equipment? | |

| 6.4.2 | Is the maintenance of the manufacturing equipment and tools controlled? | |

| 6.4.3 | Can the quality requirements be effectively monitored with the measurement and testing facilities in use? | |

| 6.4.4 | Are the work and inspection stations appropriate for the needs? | |

| P6.5 | How effective is the Process being carried out? Effectiveness, Efficiency, Waste avoidance | |

| 6.5.1 | Are there targets set for the manufacturing process? | |

| 6.5.2 | Is quality and process data collected in a way that allows analysis? | |

| 6.5.3 | In the case of deviations from product and process requirements, are the causes analyzed and the corrective actions checked for effectiveness? | |

| 6.5.4 | Are processes and products audited regularly? | |

| P6.6 | What should the Process produce? (Process Result / Output) | |

| 6.6.1 | Do the quantities/production batch sizes meet the needs and are they systematically directed to the next process step? | |

| 6.6.2 | Are products/components stored appropriately and are transport facilities/packing arrangements suitable for the special characteristics of the products/components? | |

| 6.6.3 | Are the necessary records/releases retained? | |

| 6.6.4 | Are customer requirements met at the delivery of the final product? | |

| P7 | Customer Care / Customer Satisfaction / Service | |

| 7.1 | Are all requirements related to QM-System, product, and process fulfilled? | |

| 7.2 | Is customer service guaranteed? | |

| 7.3 | Is the supply of parts guaranteed? | |

| 7.4 | If there are deviations from quality requirements, are failure analyses carried out and corrective actions implemented effectively? | |

| 7.5 | Are personnel qualified for their respective tasks and are responsibilities defined? |

|

Overall, VDA 6.3 process audits are essential for organizations aiming to enhance their operational/manufacturing processes, and customer satisfaction, maintain high standards of quality, and achieve continual improvement in the process and process quality.