All welding fixtures should be inspected as per PM plan and Welding Fixture PM Check List, and maintain proper maintenance records.

Welding Jig/Fixture Maintenance content includes the following:

- Whether the positioning pin is firm, whether it is bent or deformed, whether the positioning pin wear amount is too large, and whether the diameter of the general positioning pin and workpiece hole is not more than 0.10mm.

- Whether the positioning block is firm or not and whether the positioning surface is worn is not more than 0.2 mm.

- Whether pressure pillars can be reliably pressed, and the head wear is serious. If the head area is too small and the workpiece is pressed out of the pit, it must be grounded or replaced.

- Whether the bolts of the connecting parts are tightened securely or not, and whether the solder joints are fixed at the spot welding are cracked.

- Check whether the chute positioning is reliable and whether it moves freely.

- Whether the components of the pneumatic clamp are damaged, whether the cylinder and the pipeline leak, and whether the clamping mechanism is reliable.

- Whether the marking of welding automobile fixtures is clear.

In addition to copper positioning pins, other steel positioning pins must be heat-treated during replacement to increase wear resistance. Drawings require heat treatment when the heat-treated positioning block is replaced.

Table of Contents

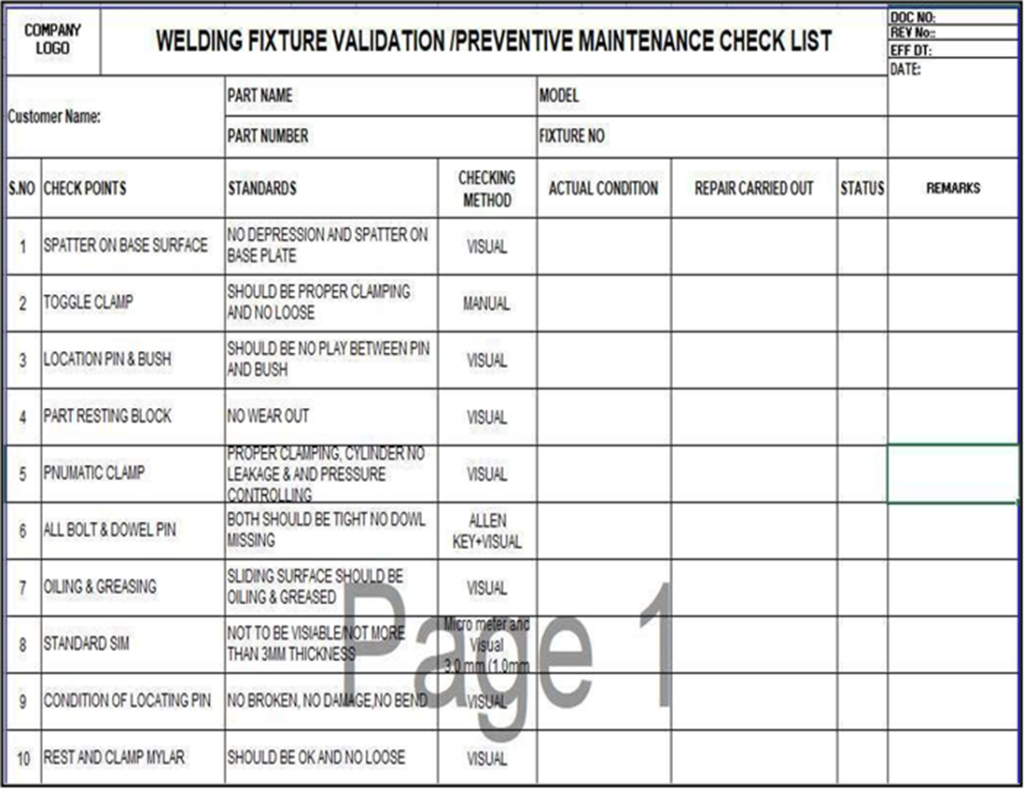

Welding Fixture Preventive Maintenance Check Sheet

Welding Jig/Fixture Checkpoints and Control

- Fixture Cleaning

- Locating Pins and Bushes

- Rest Mylar

- Clamp Mylar

- Blocks

- LM Guides

- Filter, Regulator & Lubricator

- Base Plate

- Pneumatic Tubing & Fitting

- Tooling Hole

- Poka-Yoke

- Standard SIM

- Toggle clamps

- Pneumatic Cylinder

- Magnet condition

- Part Inspection and validation

Welding Fixture PM Check List | Control Points

Welding Fixture Preventive Maintenance Checklist | Control points with control standard checking frequency:

| Control Point | Control Standard | Checking frequency |

| Fixture Cleaning | No spatter, Rust, other Contaminants etc. | Daily & Every Three Month |

| No spatter, Rust, other Contaminants, etc. | Pin diameter and Visual condition for bend, damage | Daily & Every Three Month |

| Rest & Clamp Mylar | No loose, broken, play and wear out | Every Three month |

| Blocks | No loose, broken, play and wear out | Every Three month |

| LM Guides | Easily sliding, and No play and loose | Every Three month |

| FRL Unit | Should be clean and spatter-free | Every Three month |

| Base Plate | Locating pins and bushes | Daily & Every Three Month |

| Pneumatic tubing & fitting | No Cut Spatter, Leakage & Anti spatter Tube | Every Three Month |

| Tooling Hole | No hole block | Every Three Month |

| Poka-Yoke | Must be working | Daily & Every Three Month |

| Standard SIM | Only standard sim used | Every Three Month |

| Toggle clamps | No play, clamp force, Loose | Daily & Every Three Month |

| Pneumatic Cylinder | No leakage, no part loose after clamping | Daily & Every Three Month |

| Magnet Condition | Should be available and working condition | Daily & Every Three Month |

| Inspection & Validation | As per drawing | Every Three Month |

| Copper coating spray | Should be available | Every Three Month |

Point to remember – Part must be replaced in case of any abnormality found during checking and Checking frequency can be reduced or increased based on production volume.

Critical Spare Parts of Welding Jigs/Fixtures

| Location pins | Copper Blocks | Pneumatic pipe |

| Shims | Connectors | Sensor Sleeve |

| Mylars | Reed Switches | End caps |

| Hex-Bolts | Proximity sensors | FRL Units |

| Dowel | Electrical wirings | Tooling hole covers |

| L-B01ts | Pneumatic Valves | Cylinder covers |

| Washers | Cylinders | Hand Lever |

| V-Guides | Sensor Caps | PU block/Teflon |

| Stoppers | Sensor Sleeves | Cable ties |

| Poka-Yoke Pin | Cylinder covers | Knuckle pin |

| Rough Guide | Push buttons |