In today’s industrial world, major OEM companies preferentially do business with suppliers that are making efforts to manage SOCs(Substance of Concern). The establishment of an effective Substance of Concern Management System (SoCMS) is very essential for Human Health and Environmental Safety.

A SOC Management Systemis a framework or tool used to identify, monitor, and manage hazardous substances and materials that may pose environmental and human health safety risks. It is widely used in automotive, electronics, and manufacturing industries to ensure SOCs compliance with regulations and minimize the impact of hazardous substances.

Table of Contents

Substance of Concern Management System | Key Features

- Identification: Tracks and identifies substances of concern (e.g., heavy metals, flame retardants, and toxic chemicals) in products and processes.

- Compliance: Ensures adherence to international regulations such as:

- ELV (End-of-Life Vehicle Directive)

- POPs and Phthalates

- RoHS (Restriction of Hazardous Substances)

- REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals)

- Risk Assessment: Assesses the potential impact of substances on human health, safety, and the environment.

- Substitution Planning: Aids in finding safer alternatives for hazardous materials to promote sustainability.

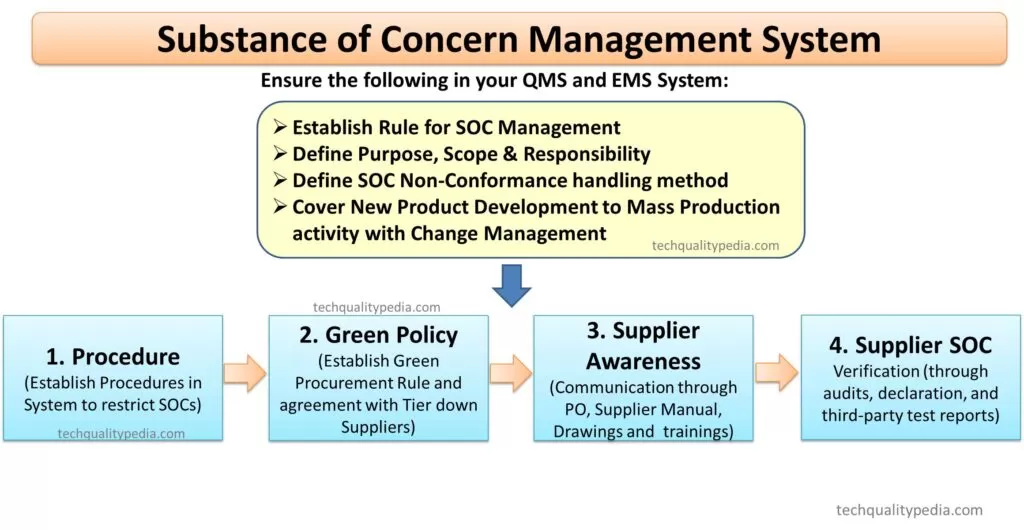

Substance of Concern Management System | Guidelines

Ensure the following in your QMS and EMS System:

- Establish Rules for SOC Management

- Define Purpose, Scope & Responsibility

- Define SOC Non-Conformance handling method

- Cover New Product Development to Mass Production activity with Change Management

1. Procedure

Establish Procedures in QMS and EMS Systems to restrict SOCs.

2. Green Policy

Establish Green Procurement Rules and Agreement with Tier down Suppliers.

3. Supplier Awareness

Communication through PO, Supplier Quality Manual, Drawings and regular trainings

4. Supplier SOC

Supplier SOC verification through audits, declaration, and third-party test reports.

How a Substance of Concern Management System Works?

1. Data Collection

- Companies collect detailed information on the materials and substances used in their Raw materials or products.

- Suppliers provide SOC material declarations, often through systems like IMDS or other material databases.

2. Substance Screening

- The collected data is screened against regulatory lists (e.g., ELV, REACH SVHC, RoHS restricted substances) requirements.

3. Risk Evaluation

- The identified SOCs(substances of concern) are evaluated for their potential impact on Human health, and Environmental safety.

- Risks are prioritized based on usage, concentration levels, and exposure scenarios.

4. Compliance and Reporting

- Organizations prepare SOC compliance reports for customers, certification bodies, or regulators.

- Detailed documentation ensures traceability and transparency throughout the supply chain.

5. Substance Substitution

- Organizations work to replace hazardous substances with safer, eco-friendly alternatives.

- Research and development teams collaborate to develop innovate materials or adjust designs.

6. Monitoring and Updates

- Regulations and industry standards are frequently updated, requiring companies to continually monitor changes.

- Substance of Concern Management System often includes automatic updates to ensure companies stay compliant.

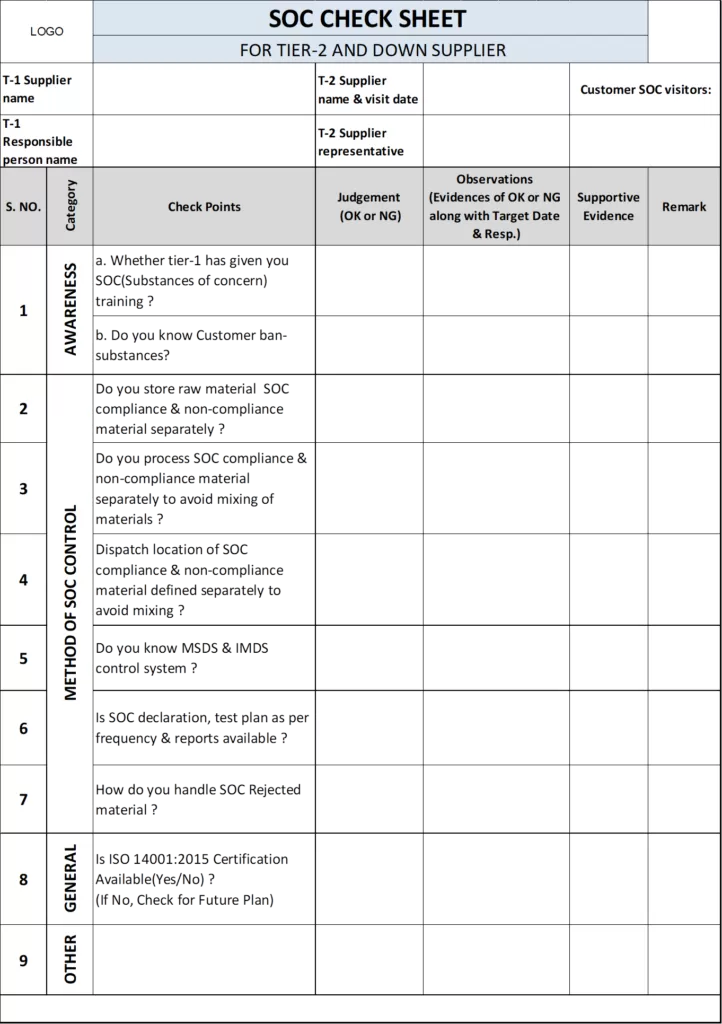

SOC Check Sheet for Tier 2 and Down Supplier

Check Sheet Control Checkpoints for SOC (Substance of Concern) Risk Identification and Assessment for Tier 2 and down suppliers are:

- Awareness

- Whether tier-1 has given you(tier-2 supplier) SOC(Substances of concern) training?

- Do you know Customer ban substances? i.e. ELV, RoHS, Asbestos, and REACH

- Method of SOC Control

- Do you store raw material SOC compliance & non-compliance material separately?

- Do you process SOC compliance & non-compliance material separately to avoid mixing of materials?

- Dispatch location of SOC compliance & non-compliance material defined separately to avoid mixing.

- Do you know the MSDS & IMDS control system?

- Is SOC declaration, and test plan as per frequency & reports available?

- How do you handle SOC Rejected material?

- General

- Is ISO 14001:2015 Certification Available(Yes/No)?