Table of Contents

What is CQI-9?

CQI-9, formally known as “CQI-9 Special Process: Heat Treat System Assessment (HTSA),” is a standard developed by the Automotive Industry Action Group (AIAG). It is designed to ensure the consistency and reliability of heat treatment processes used in the manufacturing of automotive components.

The HTSA is applicable to sites where customer-specified parts for production or service are processed throughout the automotive supply chain.

Why CQI-9?

The importance of the CQI-9 special process lies in its ability to enhance product and process quality and reliability. By adhering to this standard, manufacturers can minimize defects and improve overall performance, meeting regulatory requirements and customer expectations.

CQI Full Form

Continuous Quality Improvement.

CQI Process Approach

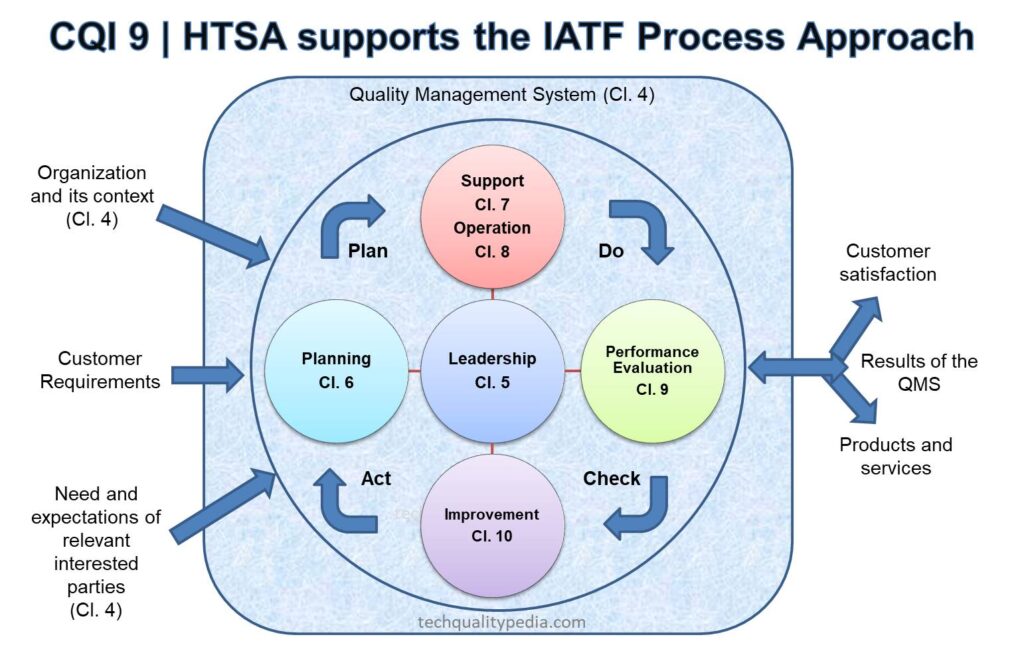

Heat Treat System Assessment (HTSA) supports the automotive process approach described in IATF 16949.

Goal | CQI-9 Process

The goal of the CQI-9 Heat Treat System Assessment (HTSA) is the development of a heat treat management system that provides for

- continual improvement

- focusing on defect prevention, and

- reduction of process variation and waste in the supply chain.

It is intended to provide a common approach to a heat treat management system for automotive production and service part organizations.

CQI-9 Application | Process Tables

All requirements of the Heat Treat System Assessment (HTSA) are generic and are intended to be applicable to all organizations performing heat treatment operations regardless of type, size, and product.

There are Nine Process Tables that are specific to the Heat Treat Processes as shown below:

Process Table A – Ferrous

- Carburizing

- Carbonitriding

- Carbon Restoration or Correction

- Neutral Hardening (Quench and Temper)

- Martempering

- Tempering

- Precipitation Hardening – Aging

Process Table B – Ferrous

- Nitriding (Gas)

- Ferritic-Nitrocarburizing (Gas or Salt)

Process Table C – Aluminum

- Aluminum Heat Treating

Process Table D – Ferrous

- Induction Heat Treating

Process Table E – Annealing, Normalizing, and Stress-Relieving

- Conformance to CQI-9 is required for organizations that perform annealing, normalizing, or stress-relieving to achieve the desired final characteristics of the part.

Process Table F – Low Pressure Processing (Carburizing/Carbonitriding/Neutral Hardening)

Process Table G – Sinter Hardening

Process Table H – Ion Nitriding

Process Table I – Hot Stamping

These Process Tables contain requirements for:

- Process and Test Equipment

- Pyrometry

- Process Monitor Frequencies

- In-Process/Final Test Frequencies

- Quenchant and Solution Test Frequencies

Assessor Qualification

To conduct the CQI-9 Heat Treat System Assessment (HTSA), the Assessor or assessing team shall:

- Possesses heat treatment knowledge.

- Minimum of 5 years of experience in

- Heat Treating or

- A combination of formal metallurgical education and heat-treating experience

- Be an experienced quality management system (QMS) internal auditor (e.g. ISO 9001, VDA and IATF 16949)

- Be familiar with the Automotive Quality Core Tools – SPC, MSA, PPAP, FMEA, and APQP.

Key Components of CQI-9

Heat Treat Process Overview

CQI9 focuses on the heat treat processes that involve heating and cooling metals to achieve desired properties. These processes are critical to attain the strength, hardness, and durability required in automotive parts.

Assessment and Evaluation

CQI9 assessments shall be conducted, at a minimum, annually, unless otherwise specified by the customer. The CQI9 standard provides guidelines for assessing and evaluating heat treat systems. This involves a thorough review of the processes, equipment, and controls to ensure they meet the required specifications.

Documentation and Records

Proper documentation is crucial in CQI9. Organizations are required to maintain detailed records of their heat treat processes, including parameters, equipment calibration, and process control measures, as well as all appropriate action plans to address any unsatisfactory ratings. The records shall be readily available for review by the customer requiring compliance to the requirements

CQI-9 Implementation Steps

Initial Steps for CQI9 Implementation are:

- Understand the Requirements: Familiarize yourself with the CQI9 standard and its requirements.

- Assess Current Processes: Evaluate your current heat treatment processes and identify any gaps or areas for improvement.

- Develop an Action Plan: Create a plan to address any deficiencies and align your processes with CQI9 requirements.

CQI-9 Training and Awareness

Educating your team about CQI9 is essential. Provide training on the standard’s requirements and ensure that all relevant personnel understand their roles and responsibilities.

Continuous Improvement

CQI-9 emphasizes the need for continuous improvement. Regularly review and update your processes to maintain compliance and improve performance.

Challenges in CQI-9 Implementation

Understanding Complex Requirements

CQI9 involves detailed and complex requirements that can be challenging to interpret and implement. It’s important to seek expert guidance if needed.

Resource Allocation

Implementing CQI9 may require significant resources, including time, money, and personnel. Planning and budgeting are essential to address these challenges.

Maintaining Compliance

Ongoing compliance with CQI9 requires continuous monitoring and improvement. Regular audits and assessments are necessary to ensure adherence.

CQI-9 Benefits

The benefits of adopting the CQI9 standard are:

- Enhanced Product Quality

- Increased Customer Satisfaction

- Regulatory Compliance

Conclusion

CQI9 is a vital standard for ensuring the quality and reliability of heat treat processes in the automotive industry. By understanding and implementing CQI9, manufacturers can achieve enhanced product quality, increased customer satisfaction, and regulatory compliance. Despite the challenges, the benefits of adopting CQI9 far outweigh the efforts, making it a valuable investment for any organization.

FAQs

1. What is the latest edition of CQI-9?

Fourth Edition, June 2020

2. What is the main purpose of CQI-9?

CQI9 aims to ensure the consistency and reliability of heat treat processes in automotive manufacturing to improve product quality and meet regulatory requirements.

3. How often should CQI-9 assessments be conducted?

CQI9 assessments shall be conducted, at a minimum, annually, unless otherwise specified by the customer to ensure continuous compliance with the Heat Treat System Assessment (HTSA). The frequency may vary depending on the organization’s specific needs and industry requirements.

4. What are the key components of a CQI-9 assessment?

Key components include evaluating the heat treat process, equipment, controls, and documentation to ensure compliance with CQI9 requirements.

5. How can organizations overcome the challenges of implementing CQI-9?

Organizations can overcome challenges by seeking expert guidance, properly allocating resources, and maintaining ongoing compliance through regular audits and assessments.