Table of Contents

CQI Meaning

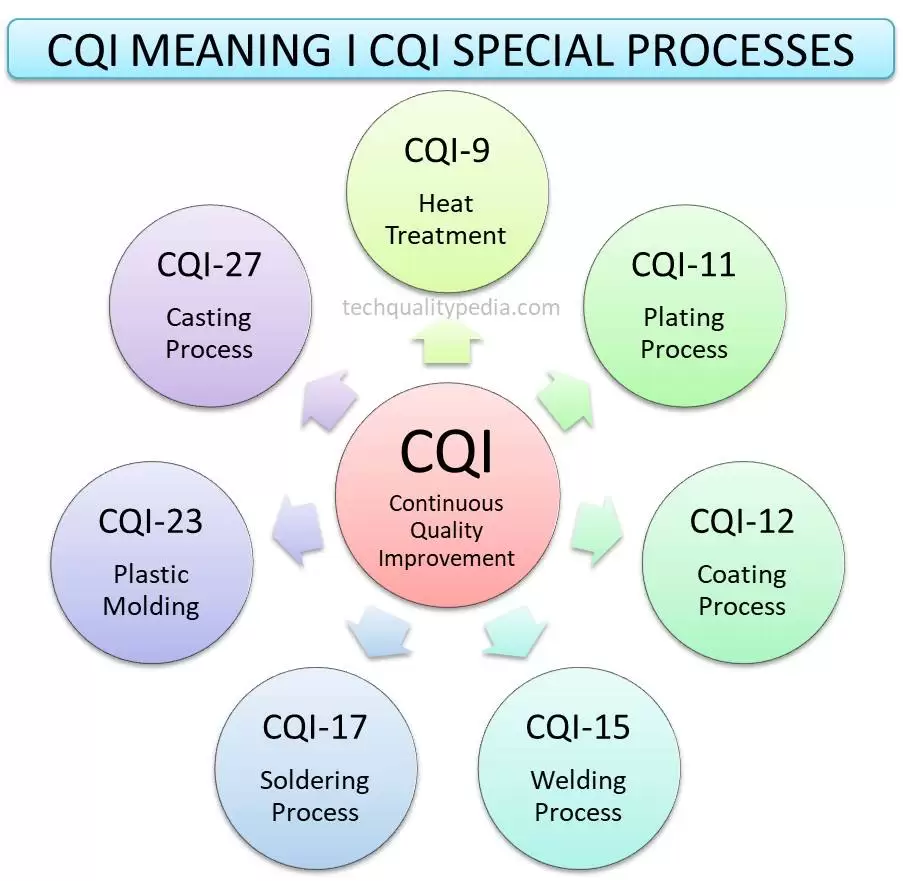

CQI Meaning – If you are working in the automotive manufacturing industry, then you have likely come across the term “CQI“. CQI stands for “Continuous Quality Improvement”. CQI is not just a general philosophy; it’s a series of structured assessment standards developed by the Automotive Industry Action Group (AIAG). CQI standards are widely applied in the automotive sector to monitor, evaluate, and improve the special manufacturing processes like Casting, Plating, Coating, Welding, Soldering, Plastic molding, and Heat treatment etc.

CQI standards aim to identify gaps, reduce process variation, and improve the effectiveness of manufacturing processes, especially those that influence safety, reliability, durability, and compliance in automotive vehicle manufacturing.

The CQI initiative includes a family of assessment documents focused on special manufacturing processes, like:

- Heat treating process (CQI-9)

- Plating process (CQI-11)

- Coating process (CQI-12)

- Welding process (CQI-15)

- Soldering process (CQI-17)

- Plastic molding (CQI-23)

- Casting process (CQI-27)

Each CQI standard provides the following:

- A process assessment checklist.

- Provides Best practices for manufacturing and quality control.

- A framework for internal quality audits or customer audits.

- A system to measure compliance.

CQI Standards

| CQI Number | Process | Focus Area |

|---|

| CQI-9 | Heat Treat System Assessment | Furnaces, Hardening, Quenching, |

| CQI-11 | Plating System Assessment | Electroplating and related processes |

| CQI-12 | Coating System Assessment | Paint, and Powder Coating |

| CQI-15 | Welding System Assessment | Spot and Arc welding, Laser welding |

| CQI-17 | Soldering System Assessment | Electronics and PCB soldering |

| CQI-23 | Molding System Assessment | Plastic injection molding |

| CQI-27 | Casting System Assessment | HPDC, GDC, LPDC and Sand Casting |

How CQI Assessment system work?

Each CQI assessment work follows a structured framework:

- CQI self-assessment checklist with defined checkpoints/questions.

- Sections for each process element.

- A rating system (Satisfactory/Unsatisfactory/Needs Improvement).

- Opportunities for improvements against the identified gaps.

- Corrective action plans for the non-conformities.

Suppliers must maintain records as part of their quality management system (typically in line with IATF 16949:2016) and do yearly self-assessments or as instructed by the customers.

Why is CQI important in the Automotive Industry?

The automotive industry requires extremely high levels of consistency, performance, reliability, and traceability. Any deviation may result in high warranty claims, high rejection, safety recalls, or decreased sales. CQI assists suppliers by:

- Reducing Cost of Quality: By addressing process quality issues in advance.

- Standardizing Processes: Aligns with OEM requirements and expectations.

- Driving Continuous Improvement: Focused system/process audits, ratings, and scorecards encourage proactive problem-solving.

- Improving Customer Satisfaction: Meets defined quality objectives or KPIs and reduces product and process non-conformance.

- Facilitating IATF 16949 and PPAP Compliance: CQI is often a mandatory requirement for supplier approval.

Conclusion

CQI is not just a catchphrase or buzzword in the automotive industrial world- it’s a way of life. From metal casting to final assembly, CQI embeds quality into every process. By applying CQI assessments like CQI-9, CQI-27, manufacturers can:

- Identify quality problems early.

- Reduce rejection, rework, and other waste or non-value-added activities.

- Enhance customer trust and satisfaction.

- Align with global quality standards like IATF 16949, VDA 6.3, etc.

CQI ensures that every item that comes off the line is reliable, secure, and consistent, regardless of whether you are a foundry, supplier, or OEM.