Gage R & R (gage repeatability and reproducibility) is the combined estimate of measurement system repeatability and reproducibility.

Gage R&R study determines whether the measurement system is acceptable or not.

In measurement system analysis, GRR study primarily focuses on two types of measurement system variations –Repeatability and Reproducibility. Both these variations are often referred to as Precision.

Table of Contents

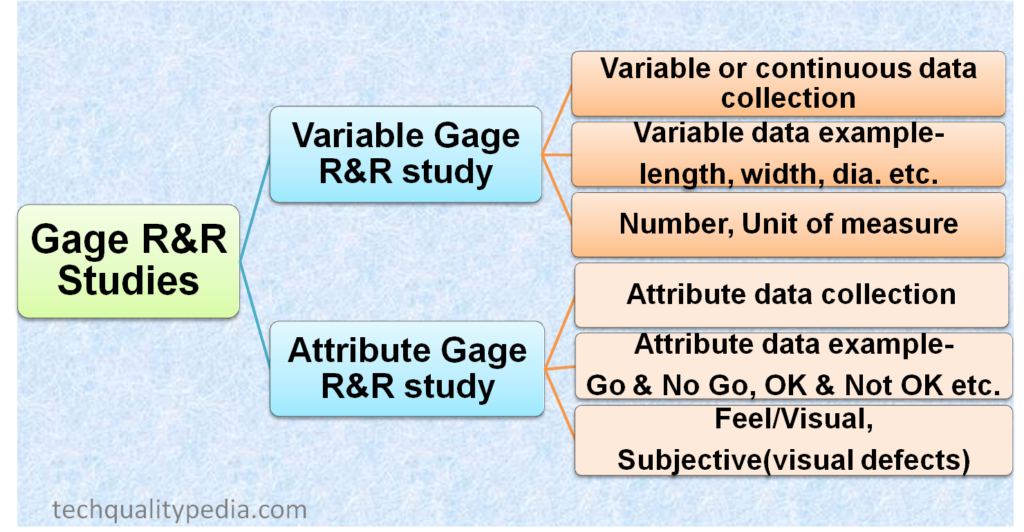

Types of Gage R&R studies

Variable Gage R&R study (Average and Range Method)

- Numbers

- Units of measure

Attribute Gage R&R study

- Feel/Visual

- Subjective (visual defects)

Variable GRR study is based on variable or continuous data collection e.g. Length, width, diameter, etc. whereas Attribute GRR study is based on the attribute data collection e.g. Go & No Go, OK & Not OK.

Why to conduct the Gage R & R study

As we know no two things are alike, there may be some variation. Variation is the law of nature and exists within all manufacturing processes and quality systems.

All collected/measurement data has some variation and GRR helps to determine the amount of variation present in the measurement data due to the measurement system. The measurement system is the combination of- personnel, equipment/gage, method and procedure, environment, software, etc.

Gage R&R study defines or determines the amount of variation present in the measurement system due to equipment and appraiser influence.

Gage repeatability and reproducibility study determine the contribution of the measurement system variation within the total variation. Total variation is the combined effect of measurement system variation (due to equipment and appraiser variation) and the manufacturing process variation.

GRR study predicts the percentage of error present in the measurement system and identifies the source of variations (equipment and appraiser) in order to improve the quality of collected data. High quality of collected data will lead to effective decision making, improve the quality of product/process, and lesser chances of error.

Variation cannot be eliminated but it can be reduced by applying various statistical quality tools and techniques like SPC, MSA, 7 QC tools, and Six Sigma.

How to Conduct Gage R&R study

For the GRR study, first of all, we need to select the equipment to be evaluated and ensure the measuring equipment is calibrated before the study commences.

After instrument/gage selection, follow the following procedure:

- Select two or three appraisers/inspectors (e.g. Appraiser A, B & C) who are users of the measurement system.

- Select samples of n (10 or more) parts randomly from the regular production run that represent the actual/expected range of process variation.

- Numbered the parts 1 through n in such a way that numbers are not visible to the appraiser.

- Now allow appraiser A to measure the n parts randomly, with an observer recording results.

- Repeat step 4 with other appraisers B and C by concealing other appraiser’s readings.

- Repeat steps 4 and 5 twice using a different random order of measurement (i.e. three repeats per part per appraiser).

- Using the average and range approach, enter the data into the form and calculate the average and ranges of all readings for each appraiser.

- Calculate the contribution of sources of system variation –

- Calculate repeatability for equipment variation(within system variation).

- Calculate reproducibility for appraiser variation(between system variation).

- Calculate GRR.

- Calculate part variation.

- Calculate total variation.

- Calculate the ndc (number of distinct categories).

- Plot the average and range graphs and analyze the numerical results for stability.

Gage R&R Acceptance Criteria

Gage R & R acceptance criteria based on the estimated value of repeatability and reproducibility (%R&R) of the measurement system.

- If Gage R & R score falls less than 10% i.e. %GRR<10%, then the measurement system is acceptable.

- If the Gage R & R greater than 10% and less than 30% i.e. 10%<%GRR<30%, then the measurement system may be conditionally acceptable based on the importance of application, cost of gage, cost of repairing, and training, etc.

- If the Gage R & R greater than 30% i.e. %GRR>30%, then the measurement system is not acceptable and needs necessary corrective actions for improvement.

Application of Gage R & R

When Repeatability is larger compared to Reproducibility then:

- The gauge needs maintenance.

- The gauge should be redesigned for more rigidity.

- The clamping or location for gauging needs to be improved.

- Excessive within-part variation.

When Reproducibility is larger compared to Repeatability then:

- The appraiser is not properly trained and needs better gauge use training.

- Incremental divisions on the instrument are not clear/readable.

- Need fixture to provide consistency in gauge use.

Gage R&R formula

Gage repeatability and reproducibility formula based on tolerance:

- Repeatability= (EV/Tolerance) x 100%

- Reproducibility= (AV/Tolerance) x 100%

where EV is equipment variation and AV is appraiser variation.