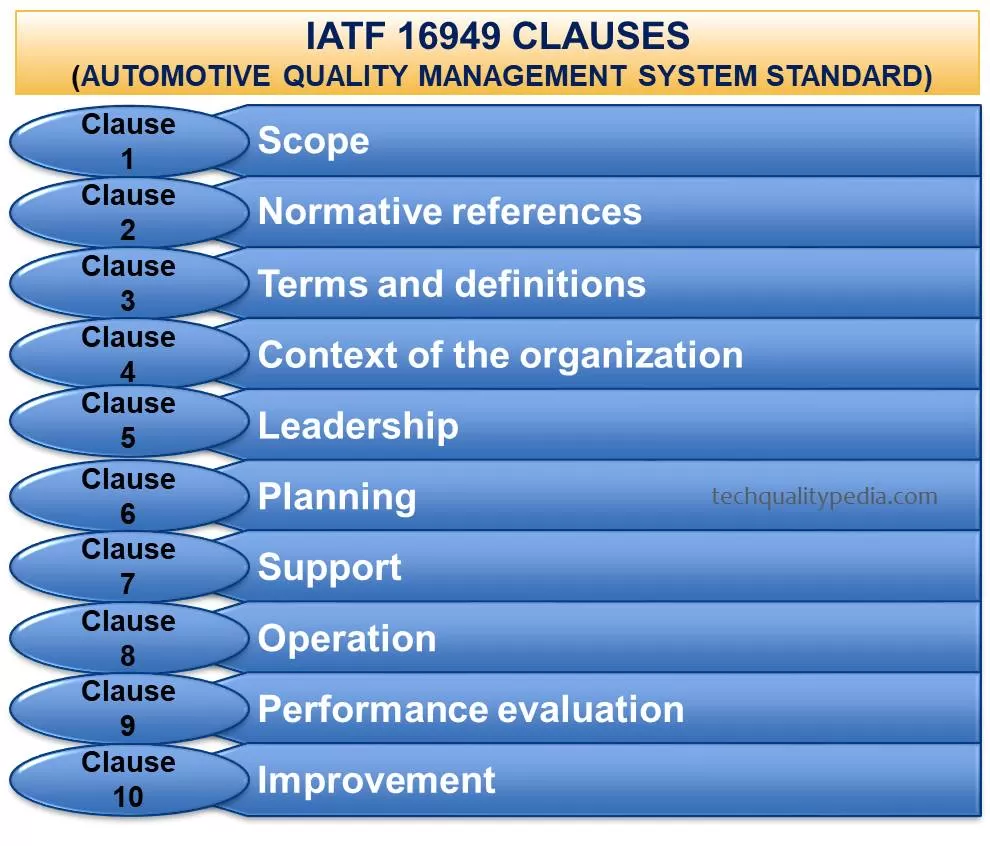

IATF stands for International Automotive Task Force. IATF 16949 is an Automotive Quality Management System Standard, also called an Automotive QMS standard. This IATF 16949:2016 standard consists of 10 clauses. Clauses 1 to 3 provide a background to the standard, and clauses 4 to 10provide the automotive Quality Management System requirements.

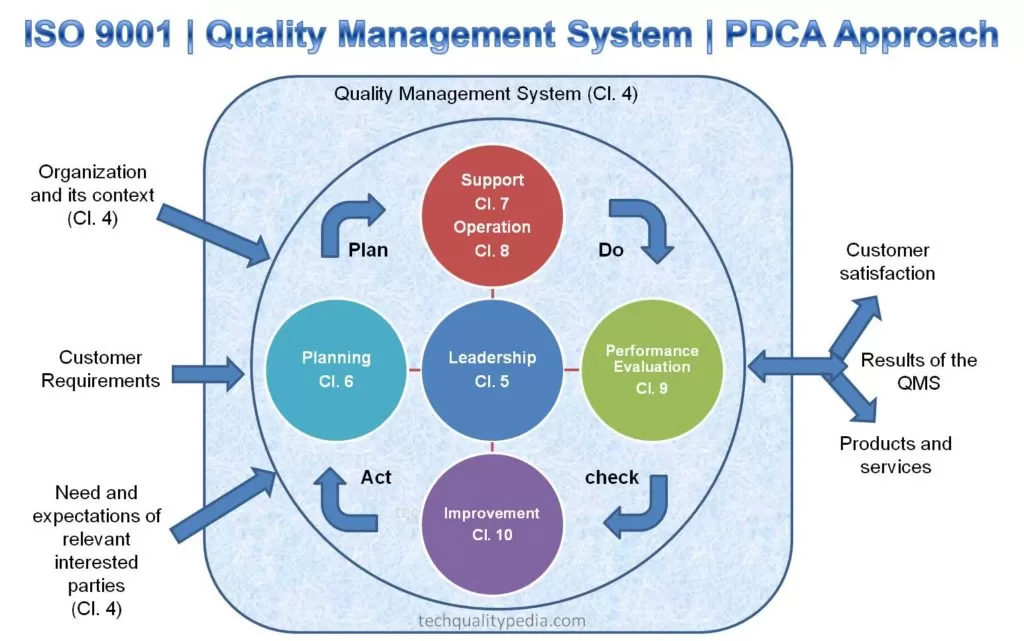

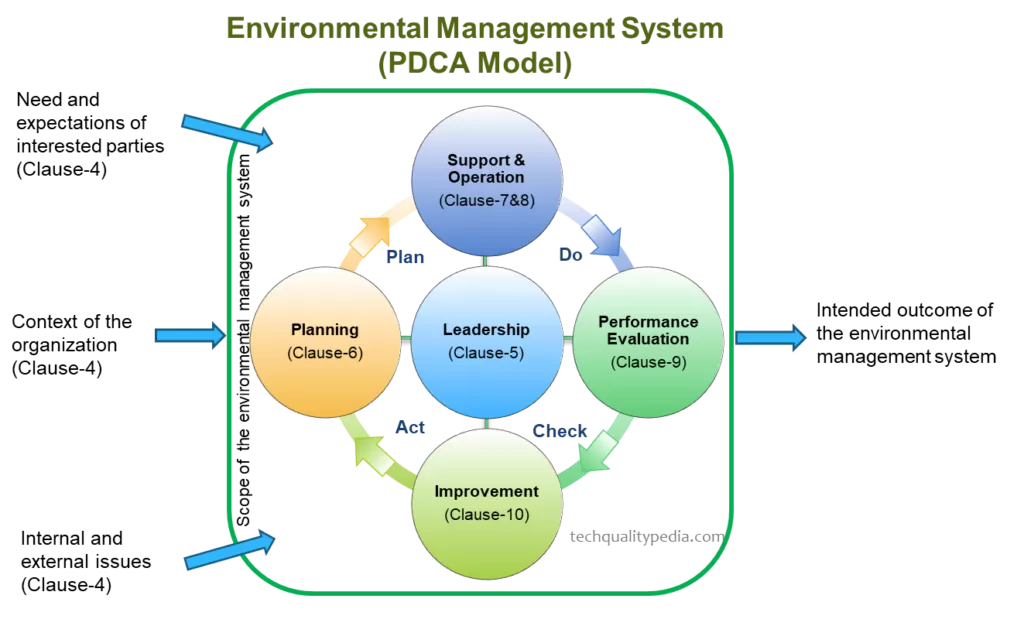

IATF16949 standard cannot be considered a standalone quality management system standard but has to be comprehended as a supplement to and used in conjunction with ISO 9001:2015.

Table of Contents

IATF 16949 CLAUSES

IATF Clause 1: Scope

- 1.1 Scope-automotive supplemental to ISO 9001:2015

IATF Clause 2: Normative References

IATF Clause 3: Terms and Definitions (See ISO 9001:2015 requirements)

- 3.1 Terms & definitions for the automotive industries.

CLAUSES OF IATF 16949 | QUALITY MANAGEMENT SYSTEM REQUIREMENTS

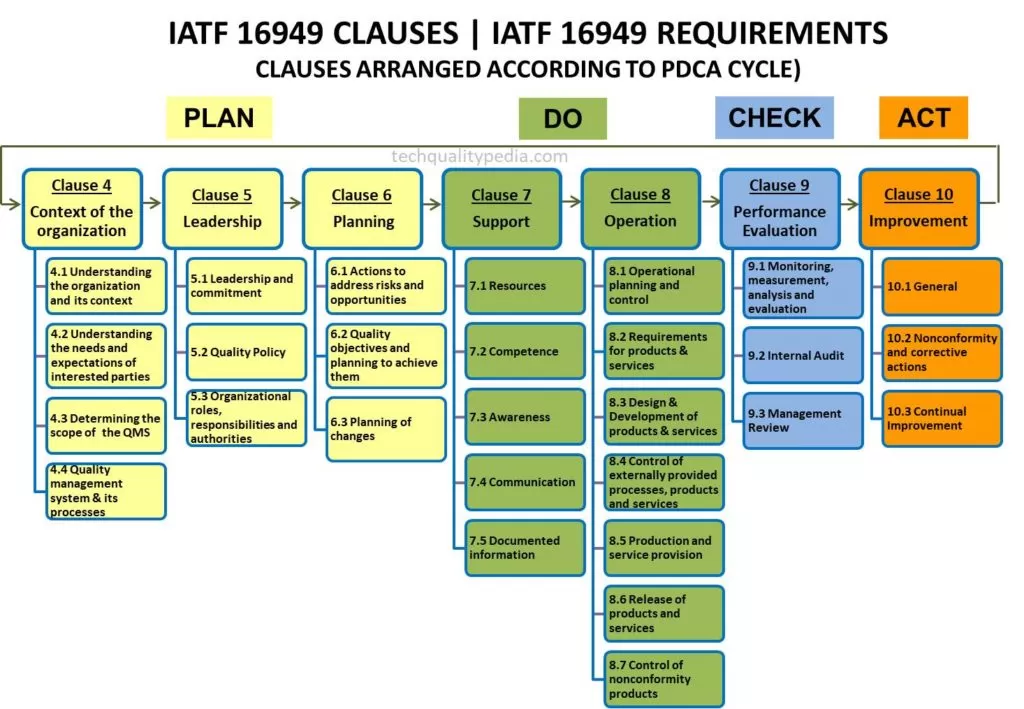

The seven mandatoryIATF 16949 standard clausesare: clauses 4 to 10. All these clauses are arranged according to PDCA model.

IATF Clause 4: Context of the Organization

- 4.1 Understanding the organization and its context.

- 4.2 Understanding the needs and expectations of interested parties.

- 4.3 Determining the scope of the quality management system.

- 4.3.1 Determining the scope of the quality management system-supplemental.

- 4.3.2 Customer-specific-requirements.

- 4.4 Quality management system & its processes.

- 4.4.1 (See ISO 9001:2015 requirements)

- 4.4.1.1 Conformance of products & processes

- 4.4.1.2 Product safety

- 4.4.2 (See ISO 9001:2015 requirements)

IATF Clause 5: Leadership

- 5.1 Leadership and Commitment

- 5.1.1 General

- 5.1.1.1 Corporate responsibility

- 5.1.1.2 Process effectiveness & efficiency.

- 5.1.1.3 Process owners

- 5.1.2 Customer focus

- 5.2 Policy

- 5.2.1 Establishing the Quality Policy.

- 5.2.2 Communicating the Quality Policy.

- 5.3 Organizational roles, responsibilities, and authorities.

- 5.3.1 Organizational roles, responsibilities and authorities-supplemental.

- 5.3.2 Responsibilities and authorities for product requirements and corrective actions.

IATF Clause 6: Planning

- 6.1 Actions to address risks and opportunities

- 6.1.1 (See ISO 9001:2015 requirements)

- 6.1.2 (See ISO 9001:2015 requirements)

- 6.1.2.1 Risk analysis

- 6.1.2.2 Preventive actions

- 6.1.2.3 Contingency plans

- 6.2 Quality objectives and planning to achieve them

- 6.2.1 (See ISO 9001:2015 requirements)

- 6.2.2 (See ISO 9001:2015 requirements)

- 6.2.2.1 Quality objectives and planning to achieve them – supplemental

- 6.3 Planning of changes

IATF Clause 7: Support

- 7.1 Resources

- 7.1.1 General (See ISO 9001:2015 requirements)

- 7.1.2 People (See ISO 9001:2015 requirements)

- 7.1.3 Infrastructure (See ISO 9001:2015 requirements)

- 7.1.3.1 Plant, facility, & equipment planning

- 7.1.4 Environment for the operation of processes (See ISO 9001:2015 requirements)

- 7.1.4.1 Environment for the operation of processes-supplemental

- 7.1.5 Monitoring & measuring resources

- 7.1.5.1 General (See ISO 9001:2015 requirements)

- 7.1.5.1.1 Measurement system analysis

- 7.1.5.2 Measurement traceability (See ISO 9001:2015 requirements)

- 7.1.5.2.1 Calibration/verification records

- 7.1.5.3 Laboratory requirements

- 7.1.5.3.1 Internal laboratory

- 7.1.5.3.2 External laboratory

- 7.1.6 Organizational knowledge (See ISO 9001:2015 requirements)

- 7.2 Competence (See ISO 9001:2015 requirements)

- 7.2.1 Competence – supplemental

- 7.2.2 Competence – on job training (OJT)

- 7.2.3 Internal Auditor Competency

- 7.2.4 Second-party auditor competency

- 7.3 Awareness (See ISO 9001:2015 requirements)

- 7.3.1 Awareness – supplemental

- 7.3.2 Employee motivation & empowerment

- 7.4 Communication (See ISO 9001:2015 requirements)

- 7.5 Documented information

- 7.5.1 General (See ISO 9001:2015 requirements)

- 7.5.1.1 Quality management system documentation

- 7.5.2 Creating & updating (See ISO 9001:2015 requirements)

- 7.5.3 Control of documented information

- 7.5.3.1 & 7.5.3.2 (See ISO 9001:2015 requirements)

- 7.5.3.2.1 Record retention

- 7.5.3.2.2 Engineering specifications

IATF Clause 8: Operation

- 8.1 Operational planning and control (See ISO 9001:2015 requirements)

- 8.1.1 Operational planning and control – supplemental

- 8.1.2 Confidentiality

- 8.2 Requirements for products & services

- 8.2.1 Customer communication (See ISO 9001:2015 requirements)

- 8.2.1.1 Customer communication – Supplemental

- 8.2.2 Determine the requirements for products & services (See ISO 9001:2015 requirements)

- 8.2.2.1 Determine the requirements for products & services – Supplemental

- 8.2.3 Review of the requirements for products & services

- 8.2.3.1 (See ISO 9001:2015 requirements)

- 8.2.3.1.1 Review of the requirements for products & services – Supplemental

- 8.2.3.1.2 Customer-designated special characteristics

- 8.2.3.1.3 Organization manufacturing feasibility

- 8.2.3.2 (See ISO 9001:2015 requirements)

- 8.2.4 Changes to requirements for products & services

- 8.3 Design & development of products & services

- 8.3.1 General (See ISO 9001:2015 requirements)

- 8.3.1.1 Design & development of products & services – supplemental

- 8.3.2 Design & development planning (See ISO 9001:2015 requirements)

- 8.3.2.1 Design & development planning – supplemental

- 8.3.2.2 Product design skills

- 8.3.2.3 Development of products with embedded software

- 8.3.3 Design & development Inputs (See ISO 9001:2015 requirements)

- 8.3.3.1 Product design input

- 8.3.3.2 Manufacturing process design input

- 8.3.3.3 Special characteristics

- 8.3.4 Design & development Control (See ISO 9001:2015 requirements)

- 8.3.4.1 Monitoring

- 8.3.4.2 Design & development validation

- 8.3.4.3 Prototype programme (see also ISO 9001:2015, clause section 8.4)

- 8.3.4.4 Product approval process

- 8.3.5 Design & development Outputs (See ISO 9001:2015 requirements)

- 8.3.5.1 Design & development outputs – supplemental

- 8.3.5.2 Manufacturing process design output

- 8.3.6 Design & development Changes (See ISO 9001:2015 requirements)

- 8.3.6.1 Design & development changes – supplemental

- 8.4 Control of externally provided processes, products and services

- 8.4.1 General (See ISO 9001:2015 requirements)

- 8.4.1.1 General – supplemental

- 8.4.1.2 Supplier selection process

- 8.4.1.3 Customer-directed sources (also known as “Directed-Buy”)

- 8.4.2 Type & extent of control (See ISO 9001:2015 requirements)

- 8.4.2.1 Type & extent of control-supplemental

- 8.4.2.2 Statutory and regulatory requirements

- 8.4.2.3 Supplier quality management system development

- 8.4.2.3.1 Automotive product related software or automotive products with embedded software

- 8.4.2.4 Supplier monitoring

- 8.4.2.4.1 Secondary-party audits

- 8.4.2.5 Supplier development

- 8.4.3 Information for external providers (See ISO 9001:2015 requirements)

- 8.4.3.1 Information for external providers – supplemental

- 8.5 Production and service provision

- 8.5.1 Control of production and service provision(See ISO 9001:2015 requirements)

- 8.5.1.1 Control Plan

- 8.5.1.2 Standardized work – operator instructions and visual standards

- 8.5.1.3 Verification of job set-ups

- 8.5.1.4 Verification after shutdown

- 8.5.1.5 Total productive maintenance

- 8.5.1.6 Management of production tooling and manufacturing test, inspection and equipment 8.5.1.7 Production scheduling

- 8.5.2 Identification and traceability (See ISO 9001:2015 requirements)

- 8.5.2.1 Identification and traceability – supplemental

- 8.5.3 Property belonging to customer or external providers (See ISO 9001:2015 requirements)

- 8.5.4 Preservation (See ISO 9001:2015 requirements)

- 8.5.5 Post-delivery activities(See ISO 9001:2015 requirements)

- 8.5.5.1 Feedback of information from service

- 8.5.5.2 Service agreement with customer

- 8.5.6 Control of changes (See ISO 9001:2015 requirements)

- 8.5.6.1 Control of changes – supplemental

- 8.5.6.1.1 Temporary change of process controls

- 8.6 Release of products and services (See ISO 9001:2015 requirements)

- 8.6.1 Release of products and services – supplemental

- 8.6.2 Layout inspection and functional testing

- 8.6.3 Appearance items

- 8.6.4 Verification and acceptance of conformity of externally provided products and services

- 8.6.5 Statutory and regulatory conformity

- 8.6.6 Acceptance criteria (refer section 9.1.1.1 also)

- 8.7 Control of nonconforming outputs

- 8.7.1 (See ISO 9001:2015 requirements)

- 8.7.1.1 Customer authorization for concession

- 8.7.1.2 Control of nonconformity products – customer specific process

- 8.7.1.3 Control of suspect product

- 8.7.1.4 Control of reworked product

- 8.7.1.5 Control of repaired product

- 8.7.1.6 Customer notification

- 8.7.1.7 Nonconforming product disposition

- 8.7.2 See ISO 9001:2015 requirement

IATF Clause 9: Performance Evaluation

- 9.1 Monitoring, measurement, analysis and evaluation

- 9.1.1 General (See ISO 9001:2015 requirements)

- 9.1.1.1 Monitoring & measurement of manufacturing processes

- 9.1.1.2 Identification of statistical tools

- 9.1.1.3 Application of statistical concepts

- 9.1.2 Customer satisfaction (See ISO 9001:2015 requirements)

- 9.1.2.1 Customer satisfaction- supplemental

- 9.2 Internal audit

- 9.2.1 & 9.2.2 See ISO 9001:2015 requirements

- 9.2.2.1 Internal audit programme

- 9.2.2.2 Quality management system audit

- 9.2.2.3 Manufacturing process audit

- 9.3 Management review

- 9.3.1 General (See ISO 9001:2015 requirements)

- 9.3.1.1 Management review – supplemental

- 9.3.2 Management review inputs

- 9.3.2.1 Management review inputs – supplemental

- 9.3.3 Management review outputs (See ISO 9001:2015 requirements)

- 9.3.3.1 Management review outputs -supplemental

IATF Clause 10: Improvement

- 10.1 General (See ISO 9001:2015 requirements)

- 10.2 Nonconformity and corrective action

- 10.2.1 & 10.2.2 See ISO 9001:2015 requirements

- 10.2.3 Problem-solving

- 10.2.4 Error-proofing

- 10.2.5 Warranty management systems

- 10.2.6 Customer complaints and field failure test analysis

- 10.3 Continual improvement (See ISO 9001:2015 requirements)

- 10.3.1 Continual improvement – supplemental

IATF 16949 clauses pdf | free download

You’ll also like:

- Quality Management System | QMS | Principles | Elements

- ISO Clauses 9001 | ISO 14001 | ISO 45001– Clause Comparison

- Clauses of ISO 14001 | Environmental Management System ISO 14001

- ISO 45001 Clauses | Occupational Health & Safety (OH&S)

- How to obtain ISO 9001 Certification?

- ISO 9001 Certification Fees | ISO 9001 Certification Body

- What is the ISO 9001? ISO 9001 2015 | Requirements | Principles

- Management Review | Management System Review

- Environmental Management System EMS | ISO 14001 standard