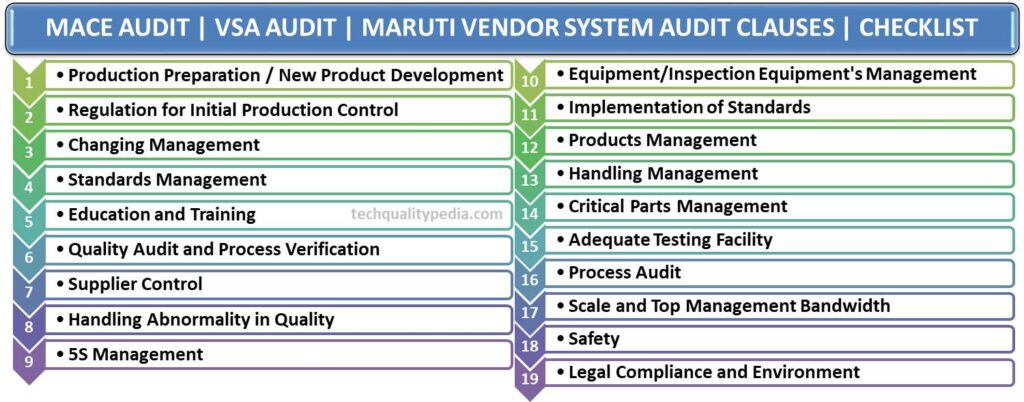

MACE stands for Maruti Suzuki Centre for Excellence, and VSA stands forVendor System Audit.

MACE Audit or Vendor System Audit (VSA) checklist consists of 19 clauses as listed below:

- Production Preparation / New Product Development

- Regulation for initial production control

- Changing Management

- Standards Management

- Education and Training

- Quality audit and process verification

- Supplier Control

- Handling Abnormality in Quality

- 5S Management

- Equipment/Inspection Equipment’s Management

- Implementation of Standards

- Products Management

- Handling Management

- Critical Parts Management

- Adequate Testing Facility

- Process Audit

- Scale and Top Management Bandwidth

- Safety

- Legal Compliance and Environment

Table of Contents

MARUTI SUZUKI TIER-2 VENDOR ASSESSMENT – QUALITY SYSTEMS (PART A)

Clause1: Production preparation / New Product Development

| Audit Area | Concerning Regulation | ||

| 1 | Regarding the implementation rule of production preparation | 1 | Do you define the procedure for Product development including the following? -scope of parts, the responsibility of each department, control contents/items? |

| 2 | Regarding management/implementation by production preparation plan/report (master plan) | 1 | Do you implement follow-up to control the schedule and progress of production preparation items? Incl top management |

| 3 | Defect prevention at the stage of process design by using FMEA/Matrix diagram | 1 | Do you consider the following items and implement corrective and preventive action to the processes and standards before regular production? -Troubles in the past; -Defect items expected; -Defect items unable to capture at customer; -Defect items difficult to repair; |

| 4 | Product/process evaluation at the quality evaluation meeting in each trial | 1 | Do you prevent defects by quality-improving activities of the cross-function team to evaluate quality performance? |

Clause2: Regulation for initial production control

| Audit Area | Concerning Regulation | ||

| 1 | Regulation for initial production control | 1 | Do you define the following items related to initial production control by standards? -controlled parts; -controlled items; -inspection method; -initial production control period; -a person who announces start/end of initial production control; -finish condition; |

| 2 | How do you define items that required special control during initial production control? Do you set stricter inspection methods than ordinary inspection? | ||

| 2 | Implementation of initial production control | 1 | Do you control process capability and defect rate during initial production control? |

Clause3: Changing Management

| Audit Area | Concerning Regulation | ||

| 1 | Definition and implementation of changing management | 1 | Do you define unexpected change (unusual) and planned change clearly? |

| 2 | Do you define procedure(rules applied from sharing information to result confirmation) at change occurrence? | ||

| 3 | Do you record product quality check results to ensure traceability? Incl retroactive checks | ||

| 2 | Definition and control method for the initial part | 1 | Do you define and control the initial part clearly? |

| 2 | Do you control initial parts separately and make quality records about them? (both internal and outsourced processes are included) |

Clause4: Standards Management

| Audit Area | Concerning Regulation | ||

| 1 | Procedure to make process control standards(QA process charts) | 1 | Do you make and review process control standards, Inspection specifications, and Operation instructions for all products which are shipped to SMC /MSIL /Tier 1? |

| 2 | Procedure to control standards ・Process control standards ・Inspection specifications ・Operation instructions | 1 | Do you have consistency to keep process control standards, inspection specification, operation inspection, and parameter chart? |

Clause5: Education and Training

| Audit Area | Concerning Regulation | ||

| 1 | Education/ training procedure | 1 | Do you clarify the department in charge of promoting quality education, and implementing education based on the annual plan? Are records of education kept? |

| 2 | Do you define and implement the skill evaluation of the operator to determine whether an operator can work without surveillance? (e.g. acceptable revel/evaluation frequency/evaluation method) | ||

| 2 | Education for managers/Inspectors/ Special operators | 1 | Do you periodically monitor the skill of certificated operators and follow up to improve their skills? |

Clause6: Quality Audit and Process Verification

| Audit Area | Concerning Regulation | ||

| 1 | Activity to keep/improve production quality | 1 | Do you conduct a quality audit to identify issues and properly improve them? |

| 2 | Content of process review | 1 | Do you confirm consistency between actual operation and standard? |

| 2 | Do you confirm if countermeasures are taken properly to prevent reoccurring quality failure? |

Clause7: Supplier Control

| Audit Area | Concerning Regulation | ||

| 1 | Evaluation method for new suppliers | 1 | Do you define criteria to certify new suppliers and implement them? |

Clause8: Handling Abnormality in Quality

| Audit Area | Concerning Regulation | ||

| 1 | Handling when an abnormal situation occurs | 1 | Do you define clearly what is an abnormal situation and make operators know the definition? |

| 2 | Do you clarify and standardize the handling rules/routes for customer claims, in-process failure, and supplier failure? | ||

| 3 | Do you have criteria to estimate the scope of a suspected lot for an abnormal situation? When an abnormal situation occurs, do you trace the suspected lot based on the criteria? | ||

| 2 | Prevention of recurrence ・Customer claims ・In process failure ・Suppliers failure | 1 | Do you prevent the recurrence of issues by analyzing the cause of occurring defects based on process investigation results such as 5-why analysis? |

| 2 | Do you reflect corrective action to the improvement of process control and review of standards? | ||

| 3 | After corrective actions are taken, do you conduct on-site checks and evaluate the effectiveness? And horizontal deployment. |

Clause9: 5S Management

| Audit Area | Concerning Regulation | ||

| 1 | Location of the production site | 1 | Do you keep store material, work-in-process, finished products, inventory, and containers at appropriate storage prevented from dust, rust, scratch, deformation, and rainwater? |

| 2 | Do you control material, work-in-process, and finished product by designated location, volume, and standard using visual control? | ||

| 3 | Do you implement inspection or critical operation under a properly controlled environment luminance /temperature/humidity/vibration/noise/work table, etc.)? | ||

| 2 | Production equipment’s management | 1 | Do you keep the condition of production equipment, jigs and tools properly? |

| 2 | Do you keep the condition of inspection equipment properly to ensure accuracy? |

Clause10: Equipment/Inspection Equipment’s Management

| Audit Area | Concerning Regulation | ||

| 1 | Maintenance of equipment, jigs, and tools | 1 | Do you conduct daily/regular checks of production equipment, dies, and jigs? Are records of maintenance kept? |

| 2 | Do you confirm regularly the function of Poka-yoke, automated stop, and alarm? Are records of maintenance kept? | ||

| 3 | Do you standardize the frequency of polishing and replacement for consumable tools(blade/electrode/rub stone, etc.)? | ||

| 2 | Maintenance of inspection equipment | 1 | Do you calibrate regularly inspection equipment and put the expire date on them? |

| 2 | Do you control the deterioration (expire date) of boundary samples for objective judgments such as appearance inspection? |

Clause11: Implementation of Standards

| Audit Area | Concerning Regulation | ||

| 1 | Implementation of standards | 1 | Do you use easy expressions (visualizer, onomatopoeia, etc.) for operation instructions? So that operator can easily understand processes and critical points. |

| 2 | Do you keep operation instructions in an accessible place and most important quality points and critical operation points in a place where operators can see them easily? | ||

| 3 | Do you regularly monitor that each operator operates according to the operation instructions? | ||

| 4 | Is it possible to judge OK/NG specifically by each check sheet (of daily equipment check, quality control report, etc.) you use? |

Clause12: Products Management

| Audit Area | Concerning Regulation | ||

| 1 | Management of parts flow | 1 | Do you keep first-in first-out of finished products and work-in-process (material, reserve parts)by using an identification tag or lot indication? |

| 2 | Do you control follows production history by product lot numbers? -production date; -production volume; -shipping date | ||

| 3 | Do you control the identification of similar parts separately? | ||

| 2 | Non-confirming parts management | 1 | Do you control the identification of non-confirming parts and parts on hold? Do you store them separately? |

| 2 | Regarding repaired non-conforming parts and parts on hold to re-use, do you define responsibility to implement? Are repair records kept? |

Clause13: Handling Management

| Audit Area | Concerning Regulation | ||

| 1 | Bins/ Trolley Management | 1 | Do you make arrangements with customers about the packing style & transportation system to prevent damage during the handling of finished products & perform accordingly? |

| 2 | Do you have a system to maintain Bins /Trolleys in Good Condition? |

Clause14: Critical Parts Management

| Audit Area | Concerning Regulation | ||

| 1 | Maru A Parts Management | 1 | Do you have Special checks/Inspections for Maru A parameters of the Maru A part available? |

| 2 | Do you have the Identification of Maru A Process/Operator on Shop Floor? | ||

| 3 | Do you keep the repair history when repairing & using Maru A items? |

Clause15: Adequate Testing Facility

| Audit Area | Concerning Regulation | ||

| 1 | Testing Facility | 1 | Does the supplier have all inspection instruments required as per drawing requirements? |

| 2 | Does the supplier have all Testing Equipment/Rigs required as per drawing requirements? | ||

| 3 | Does the Supplier has trained manpower to operate these inspection and testing instruments? |

Clause16: Process Audit

| Audit Area | Concerning Regulation | ||

| 1 | As per PCS | 1 | Conduct process audit as per process control standard |

| 2 | Closure of all the observations |

Clause17: Scale and Top Management Bandwidth

| Audit Area | Concerning Regulation | ||

| 1 | Management Bandwidth & Organization Structure | 1 | Do you have adequate organization structure and defined roles/ responsibilities for key areas such as Plant Head, Quality, Production, and Maintenance? |

| 2 | Review Mechanism | 2 | How frequently Top management visits the shop floor? How frequently Top Management monitors key performances (Performance at the customer end, in-house quality, productivity, maintenance, safety, etc.)? |

| 3 | Plant Sales Turnover* | 3 | Plant Sales Turnover for the audited plant. Group Turnover |

| 4 | PAT/Sales | 4 | PAT/Sales |

| 5 | D/E Ratios | 5 | D/E ratio |

| 6 | ROCE | 6 | ROCE |

Clause18: Safety

| Audit Area | Concerning Regulation | ||

| 1 | Working Conditions | 1 | Is the shop floor temperature, noise level, and air quality (fumes) ok? Is the layout and escape route on the shop floor Ok? Are Rest Areas/Toilets Available? Is the area/machine sufficient enough to allow easy movement of machines and tools? |

| 2 | Human and Machine Safety | 2 | Are Safety Standards made (as per process requirement) and taught to all operators? Are PPEs available as per the standards or not? |

| 3 | Machine Safety system (Door sensors etc. ) available or not? Is Safety in material movement and tools ensured or not? | ||

| 4 | Are safety standards followed on the shop floor as per the procedure? Are usage of PPEs adhered to and monitored (by supervisor/senior) on the shop floor? What accident reporting mechanism is defined? Countermeasures against accidents taken and periodic verification being done? | ||

| 3 | Fire Safety | 5 | Audit Conducted by a reputed 3rd party on MSIL defined check sheet? |

Clause19: Legal Compliance and Environment

| Audit Area | Concerning Regulation | ||

| 1 | Consent to Operate | 1 | Is consent to operate (Valid as on date) available or not? |

| 2 | ESI & PF | 2 | Are all operators enrolled for ESI and PF? Does management review the status of PF contributions /ESI payments? If ESI& PF are managed by the Contractor, then does management review and check the ESI enrolment/ payments? |

| 3 | Hazardous Waste Management | 3 | Are the different types of wastes identified on the shop floor and standards/ Procedures made? Is Segregation done at the source for different types of waste? Storage and disposal are done as per consent and periodic confirmation at the disposal stage? |

MARUTI SUZUKI TIER-2 VENDOR ASSESSMENT – EHS (PART B)

Note: The clause no. 17, 18 & 19 has been revised in the new MACE Audit Check Sheet for Tier-2 Vendor Assessment-EHS (Part B).

Clause17: Financials

| Audit Area | Concerning Regulation | ||

| 1 | Plant Sales Turnover | 1 | Plant Sales Turnover for the auditee plant. Group Turnover (Rs Cr) |

| 2 | PAT / Net Sales (%) | 2 | PAT / Net Sales (%) |

| 3 | Total Debt/ Equity Ratio (times) | 3 | Total Debt/Equity Ratio (times) |

| 4 | Return on Capital Employed (%) | 4 | Return on Capital Employed (%) |

| 5 | Internal Cash Generation / Net Sales (%) | 5 | Internal Cash Generation / Net Sales (%) |

| 6 | Debt Service Coverage Ratio (%) | 6 | Debt Service Coverage Ratio |

| 7 | Current Ratio (times) | 7 | Current Ratio (times) |

Clause18: Safety

| Audit Area | Concerning Regulation | ||

| 1 | Working Conditions | 1 | Is layout and escape route on shop floor OK? |

| 2 | Is Machine Area sufficient enough to allow easy movement of workforce and tools. | ||

| 3 | Is shop floor temp, noise level, air quality (fumes) ok? Is Rest Area/Toilets Available? | ||

| 2 | Human and Machine Safety | 1 | Does supplier have safety policy? |

| 2 | Is Responsibility of Safety related activities defined to specific personnel with in the company. | ||

| 3 | Are Safety Standards made (as per process requirement) | ||

| 4 | Are safety standards training provided to all and followed on shop floor as per the procedure? | ||

| 5 | Are Operation Control Procedures (OCP/SOP) available wrt Safety & followed properly? | ||

| 6 | Fire fighting Training and First Aid training given to workers | ||

| 7 | Are Machine Safety systems (Sensors, Two Hand Push Button, Machine Guarding, Emergency Switches, Mechanical Stopper, Cam Guard, etc.) available, As applicable as per Annexure – 1/2? (Ok if all safety condition is OK on all Machines) | ||

| 8 | Is Safety in material movement and tools ensured or not? Defined procedures to be Checked. | ||

| 9 | Are PPEs defined as per process and followed as per standards or not? | ||

| 10 | Accident reporting mechanism defined? | ||

| 11 | Accidents Data available and maintained? | ||

| 12 | Countermeasures against accidents taken and periodic verification being done ? | ||

| 13 | Availability of Medical/ First Aid? | ||

| 14 | Materials Handling Procedure Defined and adhered? | ||

| 15 | Is Risk Assessment done and documented for Routine and Non Routine Activities. Documents to be verified. | ||

| 16 | Are pits and floor openings covered or otherwise guarded? | ||

| 17 | Are paint spray booths, dip tanks, Exhaust Ducts etc. Cleaned regularly? | ||

| 18 | Lockout/Tagout Procedures established and rigidly followed? | ||

| 19 | Are License, operating permits and records up-to-date for such items as Lift, Boiler, air pressure tanks, and liquefied petroleum gas tanks? | ||

| 20 | Is HSD Storage license (>2500) Available? | ||

| 3 | Fire Safety | 1 | Audit Conducted by reputed 3rd party on MSIL defined check sheet? < Audit report should not be more than 3 Years old, if Green and not more than 1 Year old if not green> |

| 2 | Countermeasure Plan available with defined timelines (not more than 6 months from date of audit) |

Clause19: Top Management bandwidth & HR Practices

| Audit Area | Concerning Regulation | ||

| 1 | Management Bandwidth & Organization Structure | 1 | Do you have adequate organisation structure and defined roles/ responsibilities for key areas such as Plant Head, Quality, Production, Maintenance and Safety? |

| 2 | Is HR Structure and HR person Available and responsibilities defined | ||

| 2 | Review Mechanism | 1 | Does Top Management monitors the Safety parameters and verify the countermeasures implemented on monthly basis? |

| 3 | Statutory Compliance | 1 | Is Child Labour Policy Available ? (not less than 14 years) |

| 2 | Is Minimum wage being paid as per skill level ? | ||

| 3 | Factory license Available and valid? | ||

| 4 | Contractor license Available and valid? | ||

| 5 | Standing orders there or not. (appl. where >100 workmen are employed on any day of the last 1 year) | ||

| 6 | Is POSH policy available and compulsory trainings given for the same. | ||

| 4 | Consent to Operate | 1 | Consent to operate (Valid as on date) available or not (Air & Water)? |

| 5 | ESI & PF | 1 | Are eligible workers or employees, are covered or entitled under ESI? |

| 2 | Is PF contribution of employees and employers are done ? (The due date for Monthly Challan remittance to Bank for PF is 15th of Every Month) | ||

| 3 | Management reviews the status of ESI/ PF contributions payment? (Due date for payment of ESIC is 15th of following month.) | ||

| 4 | If ESI & PF managed by Contractor, then does management reviews and checks the ESI enrolment/ payments? | ||

| 6 | Hazardous Waste Management | 1 | Are different type of wastes identified on shop floor and standards/ Procedures made? |

| 2 | Is Segregation done at source for different type of wastes? Storage and disposal being done as per consent and periodic confirmation at disposal stage? |