Red bin analysis is a process by which the rejected parts are being recorded, analysed, and necessary corrective measures are being taken on daily, weekly and monthly basis by cross function team (CFT) to prevent defect re-occurrence.

Red bin analysis in quality is a process of sorting out and to verify the defects generation/occurrence on production lines including quality inspection stages on a daily/weekly/monthly basis, and then investigate the root cause of defects (using Cause & Effect Analysis & 5-Why Analysis quality tools) for initiating corrective actions as early as possible.

Red bin analysis is applicable to all the kind of rejections at various manufacturing/ production processes within organization.

Table of Contents

Purpose of Red Bin Analysis

- To ensure that necessary actions are being taken on daily/weekly/monthly basis against in-house rejections.

- To reduce rejection level (In %age or PPM).

- To reduce Cost of Poor Quality (COPQ).

- To prevent defect outflow to customer end.

- To prevent defect re-occurrence/regeneration.

- Helps to identify where to take necessary countermeasures.

Steps of Red Bin Analysis

- Put all defective parts in the red bin when detected. (Red Bin should be kept near to operator or below the machine).

- Do red marking on the defective area of the parts.

- Put an identification tag on defective parts. Identification tag should have information like p-art name/ part number, quantity, date, shift, machine number, shop & reason of rejection etc.

- Prepare a cross functional team(CFT) for the Red bin analysis meeting.

- Define suitable location for red bin analysis meeting.

- Determine the specified time for the red bin meeting.

- Carefully verify the defective parts during the red bin meeting.

- Conduct brainstorming with CFT to identify potential causes. Involve operators while identifying the potential causes of the problem/defect. Use fishbone diagram of seven quality tools for identifying the potential causes.

- Also verify the defect by visiting a place of occurrence, follow 3G rule.

- After identifying the potential causes, do the why why analysis with the team to find out the real root cause of the problem.

- Take countermeasure against the identified real root cause.

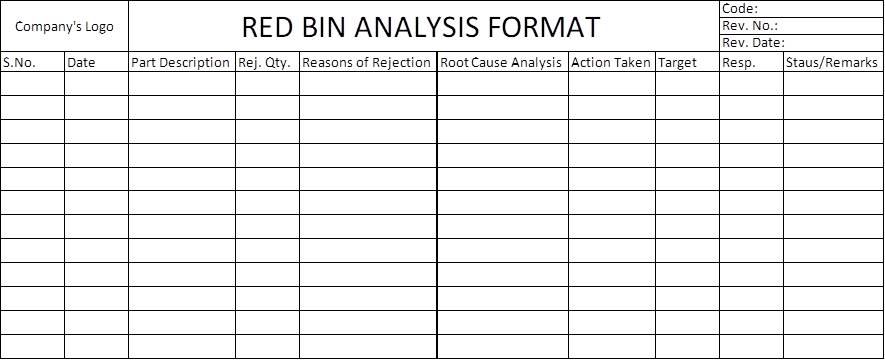

- Maintain the record of daily red bin meeting in red bin analysis format as shown.

- Maintain attendance record of each red bin meeting.

- Check effectiveness of the action taken.

Red Bin Analysis Format

Download red bin analysis excel template