Table of Contents

What is Safety?

Safety is prevention of accidents which results personal injury and property damage.

Safety in a industrial establishment is required to avoid any interruptions into all the below factors:

Man, Machine, Material and Environment.

Safety Management Principle

- Safety is everyone’s responsibility

- Good result can not be obtained without unified safety consciousness.

- Safety takes priority over everything else i.e. Safety First

- First priority must always be given to safety to protect “Employees”.

- All industrial accidents are preventable

- Dangerous environment is the factor of the industrial accidents.

- Industrial accidents are preventable if we eliminate the danger.

Safety Audit Purpose

- To identify unsafe conditions/unsafe acts

- To find out ways and means to implement preventive actions

- To ensure employee participation in accident prevention

- To evaluate & compare the safety performance level within departments

- To register the upward communication on safety issues

- To create a safe work place

- To fulfill legal compliance

Who Secure Safety ?

Safety should be secured by all the members.

Safety Audit Methodology

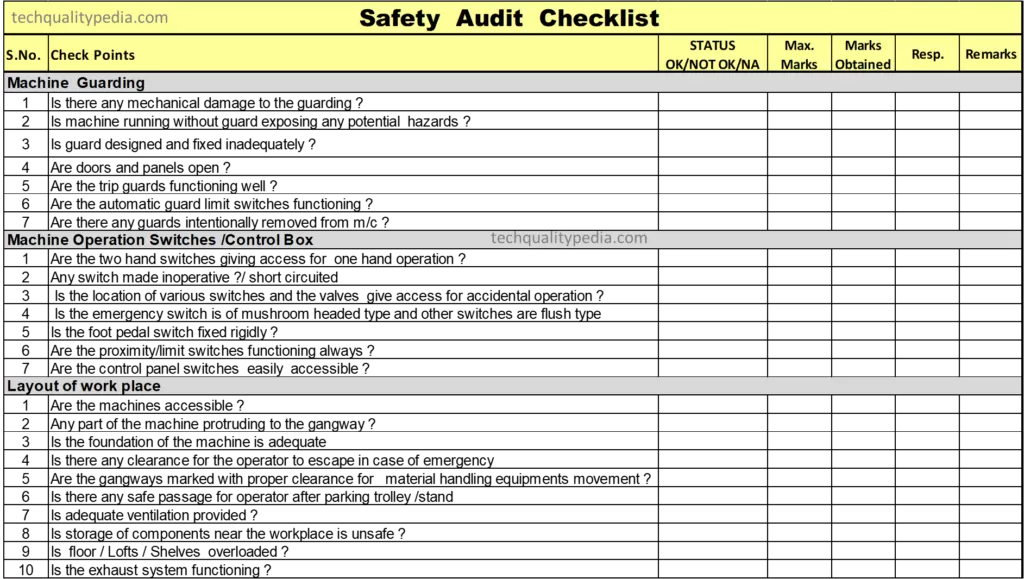

- Prepare Safety Audit Checklist for conducting audit

- Identify key persons to conduct the conduct the audit

- Adequately train the identified key persons

- Select a department /Area /Section

- Conduct the audit once in month comprehensively

- Record the findings in the defined format

- If possible, take a photograph of the non-conformity as evidence

- Put a tag explaining the non-conformity

- Number the tag and category or criteria

- Present them in the Safety committee meeting

- Suggest countermeasure and preventive measure

- Send minutes of meeting to the concerned process owners (HODs)

- Follow the progress of action

- Re-audit the same if the non-conformities existing

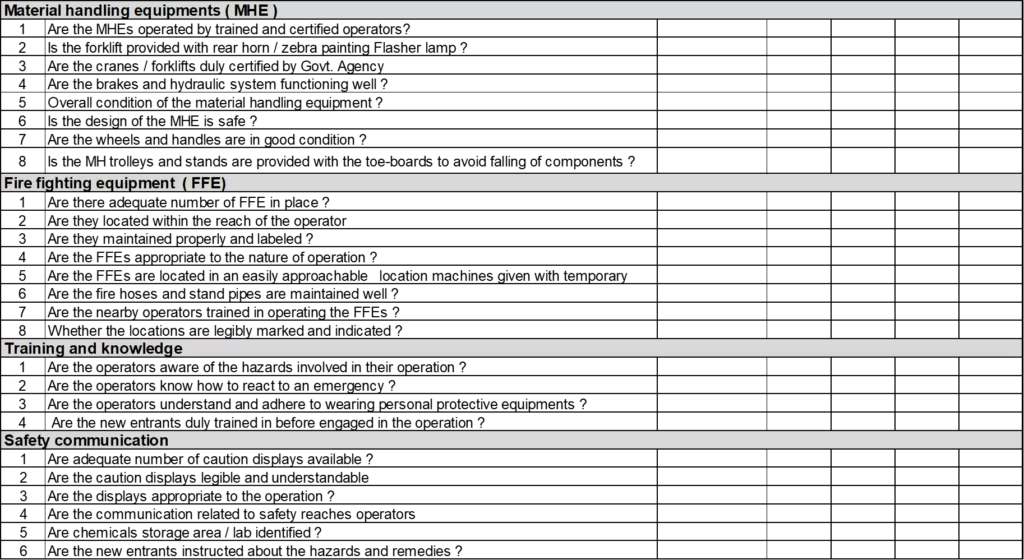

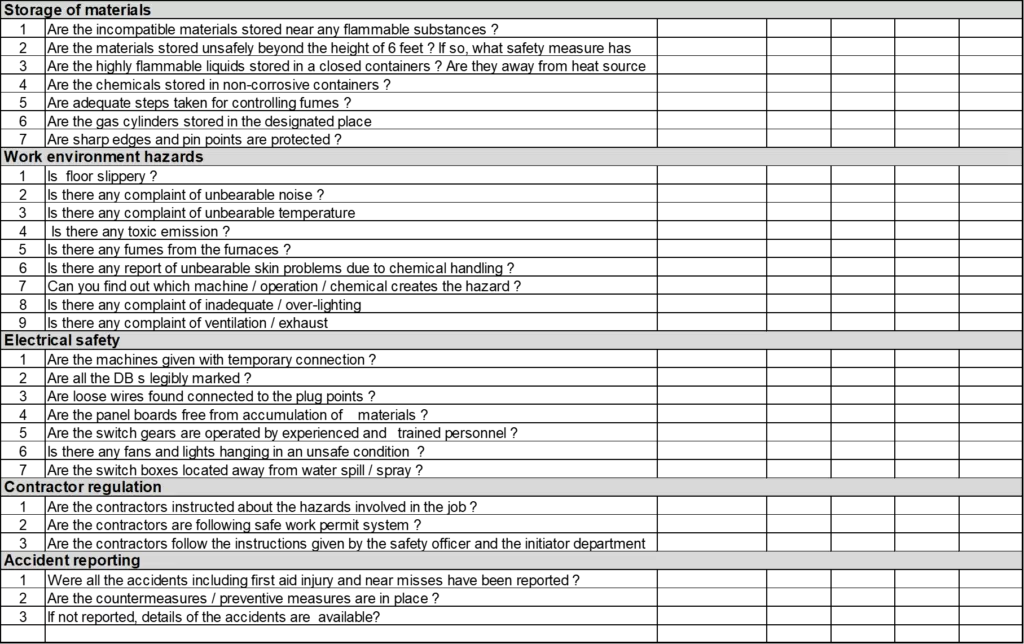

Types of Safety Audit

The Safety Audit types in manufacturing industries are:

- Material Handling Equipments

- Machine Guarding

- Electrical Safety

- Fire Fighting Equipments

- Safety Switches

- Layout of Machines

- Training and knowledge of operators

- Chemical Handling

- Safety Communication

- Contractors Regulation

- Storage of Materials

- Work Environment Hazards

- ISO 14001 Environmental Management Standard

- OHSAS 18001/ISO 45001 Occupational Health & Safety Management Standard

Prepare Safety Audit checklist by addressing all above safety points.

Marks Criteria:

For 100% Compliance :- 2 Marks

50% Compliance :- 1 Mark

Poor condition/Not follow :- 0 Mark

Not Applicable :- NA

-> No good work without safe working environment

-> No good quality without good work

-> No productivity improvement without good quality