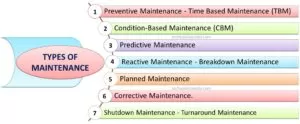

In manufacturing industries, plant maintenance refers to the activities and processes undertaken to ensure the proper functioning, reliability, and longevity of equipment, facilities, and infrastructure. There are several Types of Maintenance processes that organizations may implement:

- Preventive Maintenance or Time-Based Maintenance (TBM)

- Condition-Based Maintenance (CBM)

- Predictive maintenance

- Reactive Maintenance – Breakdown Maintenance

- Planned Maintenance

- Corrective Maintenance.

- Shutdown Maintenance – Turnaround Maintenance

- Total Productive Maintenance (TPM)

Table of Contents

TYPE OF MAINTENANCE | MAINTENANCE CATEGORY

The several Type of Maintenance processes or Maintenance Categories used in the organizations are briefly described:

Preventive Maintenance

Preventive maintenance is a proactive approach that includes scheduled inspections, servicing, and repairs to prevent equipment failure. It aims to identify and address potential issues before they cause significant disruptions or breakdowns.

Condition-Based Maintenance

Condition-based maintenance relies on the continuous monitoring of equipment conditions using sensors and data analysis. It involves performing maintenance activities based on real-time equipment health and performance data, optimizing maintenance efforts and resources.

Predictive Maintenance

Predictive maintenance relies on advanced technologies and data analysis to identify patterns or indicators of equipment failures. It involves monitoring parameters such as vibration, temperature, and pressure to detect deviations from normal operating conditions. By predicting failures, organizations can perform maintenance activities at the optimal time, reducing downtime and minimizing costs.

Benefits of Predictive maintenance

- Reduced Maintenance costs

- Fewer Machine Failures

- Reduced Downtime

- Reduction in Stocking

- Increased Lifespan of Machinery

- Mean Time Between Failure Estimations

- Increased Production

- Increased Operator Safety

- Higher Profits

Reactive Maintenance (Breakdown Maintenance)

This type of maintenance is performed in response to equipment breakdowns or failures. It involves repairing or replacing damaged components or systems to restore functionality quickly.

Planned Maintenance

Planned maintenance involves scheduling maintenance activities in advance based on predetermined criteria. It ensures that maintenance tasks are performed regularly to prevent equipment deterioration and promote optimal performance.

Corrective Maintenance

Corrective maintenance involves fixing equipment or systems after they have failed or experienced a significant deviation from normal operating conditions. It focuses on identifying and addressing the root causes of failures to prevent recurring issues.

Shutdown Maintenance (Turnaround Maintenance)

Shutdown maintenance refers to the comprehensive maintenance activities undertaken during planned shutdowns or scheduled plant downtime. It includes inspections, repairs, and upgrades that cannot be carried out during regular operation.

Total Productive Maintenance (TPM)

TPM is a holistic approach that aims to maximize the overall equipment effectiveness-OEE and reliability of the systems. It involves involving all levels of the organization to actively participate in maintenance activities, including operators, maintenance personnel, and management.

These types of maintenance can be implemented individually or in combination, depending on the specific needs and requirements of the manufacturing facility. The goal is to ensure optimal uptime, minimize disruptions, extend equipment life, and reduce overall maintenance costs.

Time-Based Preventive Maintenance

Time-based maintenance, also called periodic maintenance, refers to routine maintenance tasks performed on an asset at fixed time intervals, regardless of its condition.

Calendar or time-based preventive maintenance occurs at a scheduled time, based on a calendar interval. The maintenance action is triggered when the due date approaches and necessary work orders have been created.

Benefits of Time – based maintenance

- Minimal Training: Time –based tasks are simple and usually do not require extensive training to learn.

- Lower Long – Term cost: Compared to breakdown or corrective maintenance, time – based maintenance is inexpensive.

- Easy to Implement: Time-based maintenance does not require additional sensors or equipment to decide when assets require service.

- Predictable schedule: Since time – based maintenance follows a set time interval; maintenance schedules are consistent and predictable.

- Effective for continuously running Assets: Wear and tear is more predictable for assets that run continuously, allowing maintenance work to be scheduled at regular intervals.

Prescriptive Maintenance

Prescriptive maintenance is an advanced maintenance strategy that utilizes data analytics, condition monitoring sensors, and artificial intelligence to predict equipment failures and recommend specifics actions to prevent them.

Prescriptive maintenance is the asset maintenance strategy that uses machine learning to adjust operating conditions for desired outcomes, as well as intelligently schedule and plan asset maintenance.

Benefits of Prescriptive maintenance

- Develop predictive maintenance models for maximizing asset life, operational performance, or uptime.

- Leverage historical data and real- time data.

- Optimize maintenance operations.

- Minimize downtime and increase efficiency.

Preventive Maintenance Benefits

Start getting maximum utility from your assets and achieve cost savings by pursuing a preventive maintenance strategy.

Reduces Unplanned Downtime.

Identify repairs earlier in the asset lifecycle for always-on operations that reduce downtime and optimize production.

Extends Equipment/Asset Life

Systematically schedule maintenance and inspections to ensure assets achieve their full lifecycle and warranties are kept up to date.

Reduces Maintenance Costs

Manage planned and unplanned maintenance, inventory, and spare parts costs. Better insight into your operations and assets helps you make a significant reduction in maintenance costs.

Enhance Productivity

Productivity boosts due to the increased machine operating time, Improvement in MTTR & MTBF, reduction in unplanned downtime/stoppages.